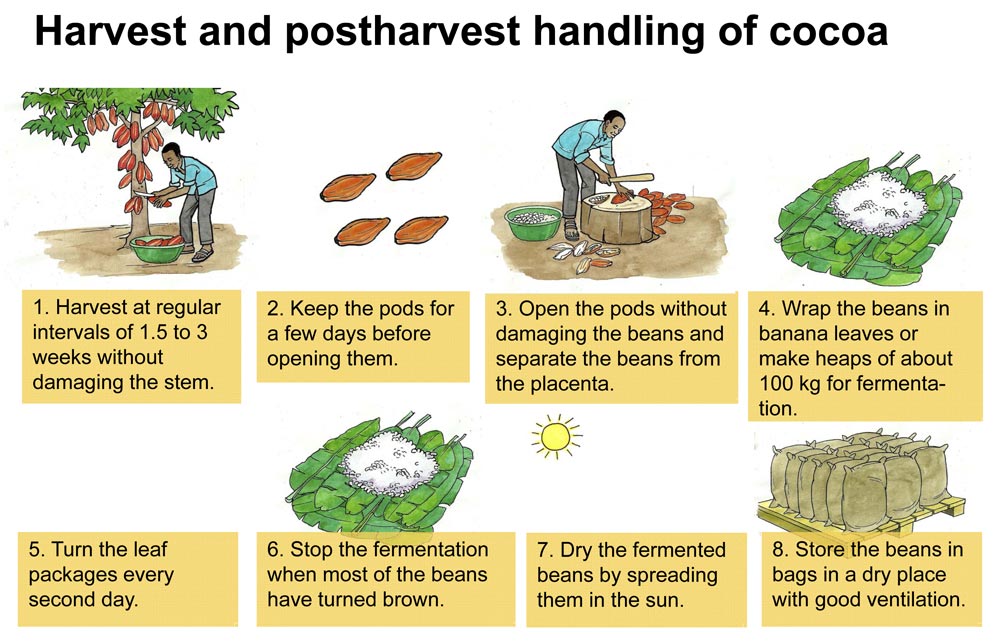

Post-harvest handling of cocoa

Substantial quality characteristics of cocoa depend on correct processing, which starts already with the harvesting process and ends with the storing of the processed product.

Fermentation

Beans must be fermented as soon as they are removed from the pod. Fermentation has four objectives:

- Removes the mucilage (pulp) attached to the beans.

- Kills the embryo so that the beans cannot germinate.

- Encourages chemical changes within the bean, which produce the substances responsible for the chocolate aroma.

- Reduces the moisture content of the beans.

Fermentation can be carried out in two ways:

Traditionally the beans are heaped or wrapped in banana leaves. Every second day the banana leaf packages are turned over to ensure even fermentation. The size of heaps is determined by the need for a sufficiently high temperature of 40 to 50 °C to permit liquid to drain out and air to circulate freely around the beans.

Small quantities of less than about 70 kg will not reach the required temperature, while in heaps of more than 150 kg aeration becomes restricted. The end of the fermentation process is reached when most of the beans are brown. When 75 % of the beans have pale cotyledons in the centre with a brown ring, the fermentation process should be stopped. The process usually takes 6 to 8 days for Forastero and 3 to 5 days for Criollo cocoa.

A second way of fermenting the cocoa beans is by placing them in wooden tray stacked on top of each other and covered. This way saves on work for the farmer and ensures better fermentation. Waste water from the fermentation process should be properly disposed off, for example in other crop fields. Germinated beans and beans from disease-infested pods should be fermented separately.

Proper drying

Fermented beans must be dried to prevent deterioration. This is mainly done by spreading them out in the sun on concrete floors or raised mats. The beans need to be covered overnight and in rain. Sun drying alone will take at least a week. Foreign matter should be picked out from the beans while they are spread out. Sun drying can be supplemented with hot air in specially-designed drying chambers.

Well-dried beans should have a moisture content of about 6 to 7 %. Beans with a moisture content of more than 8 % become mouldy, while beans with moisture below 5 % become brittle. Before packing dried beans into air permeable bags, all flat, broken and poorly fermented beans should be removed.

Proper storage

Due to the high temperature and humidity in the tropics, stored cocoa rapidly gets attacked by storage pests and moulds, because dried cocoa easily absorbs water. In locations with 80 to 90 % humidity, the moisture content of cocoa often increases to more than 10 %. As a result, cocoa loses its storage capacity. Therefore, for proper storage good ventilation should be ensured. The bags should be stack off the ground, preferably on wooden pallets, and off the wall. Organic production does neither allow the treatment with methyl bromide nor the application of synthetic storage insecticides. The jute bags used for packing should also not have been treated with pesticides.

Marketing and organic certification of organic cocoa

Sustainable production of cocoa has become an increasingly important driver for the development of the cocoa sector in Africa. Driven by consumer demand, new initiatives have emerged, including commitments by cocoa importers and chocolate manufacturers to purchase sustainably certified cocoa and to provide services to producers. Because of these developments there is a growing market for sustainably produced and certified organic cocoa in Europe and the US. This trend provides an opportunity for cocoa producers to improve their livelihoods, and for the cocoa sector to make its sustainability efforts more visible. To realize this opportunity, producers need support to access these emerging markets.

There are different sustainability initiatives to certify cocoa, which include organic production, and others like ‘Rain Forest Alliance’, ’Fairtrade’ and UTZ Certified which are mainly social standards, but also require ‘good practices in cocoa production’.

Organic certification of cocoa should only be done as a market requirement.

Generally organic production of cocoa will have the following requirements:

- Implementation of organic approaches to soil fertility, pest and disease management. Organic production does not allow the use of synthetic pesticides and fertilisers as well as other unnatural postharvest treatments for cocoa beans, packaging materials and stores.

- Proper separation of organic cocoa and conventional cocoa during production and postharvest handling

- Implementing a good traceability system, based on clear labelling and record keeping in order to minimise contamination.

- In order to reduce organic certification cost for the individual farmer, smallholder farmers should look for group certification.

Specific national or international organic standards may define additional requirements. Therefore, interested cocoa farmers should consult the national organic movement or organic certification body operating within the region or country for further guidance.

Email: Editor@agricinafrica.com

Comments

Post a Comment