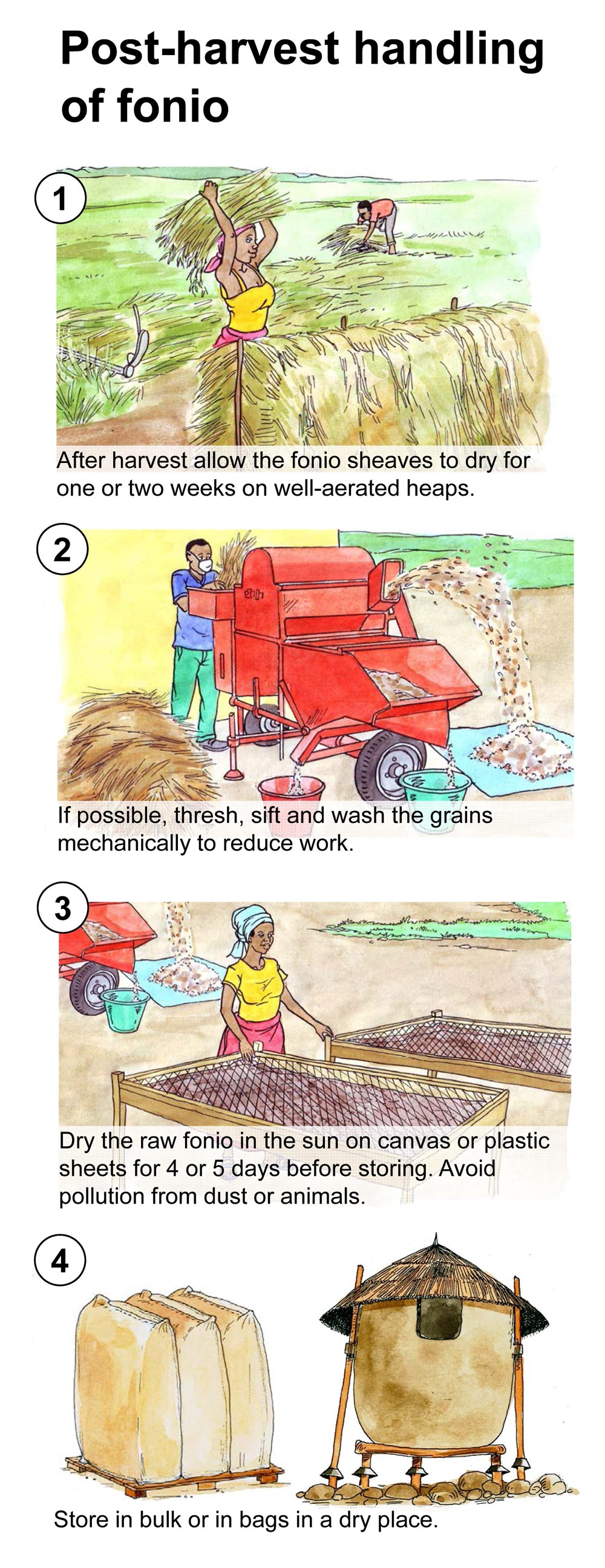

Pre-drying

After harvesting, the fonio sheaves are dried for about one or two weeks (or more), before being threshed. Well-dried straw is relevant for mechanical threshing.

For drying, the sheaves are piled to round or oblong heaps on the edge of the field, built on simple wooden structures to improve aeration. In humid con-ditions such heaps may develop heat due to insuffi cient aeration and decomposition processes, or may encourage development of moulds. Both reduce the quality of the grains and can result in grain losses. Therefore, such heaps must be controlled regularly and must be disassembled as soon as they develop heat inside.

Threshing and sifting

Traditionally, threshing is done by hand, which is very laborious. Also, traditional threshing on non-paved soil results in high rates of sand contamination, whereas threshing on a paved surface is somewhat better. Threshing on a canvas is considered being best when threshing manually.

For mechanical threshing rice threshing machines were adapted to be used for fonio, processing 250 to 300 kg of grains per hour. Shifting from manual to mechanical processing can give farmers benefi ts, which are much higher than the investments. Mechanising the processing proves essential to reduce work and improve the quality and availability of marketed fonio. However, the relatively high costs to buy a threshing machine may be a constraint to some farmers. To reduce the costs, farmers should form groups to buy machines at village level, or threshing services should be provided to the farmers by the private sector.

Sifting of the grains after threshing removes part of the sand, which otherwise would wear down machines in further processing and would need to be removed for food production anyhow.

Drying

Threshed fonio, which is also called ‘fonio paddy’ or ‘raw fonio’, needs further drying for 4 to 5 days, as the hulls still remain on the grains. Fonio paddy is usually dried on traditional mats or on canvas or plastic sheets in the sun. The grains are suffi ciently dry, when they run easily through the fi ngers (moisture content lower than 11 %).

Storage

Well-dried fonio grains store well and can be kept for many months or even years. They are not liable to damage by storage pests. For storage the grains are usually filled in bulk into traditional clay granaries. Or the product is stored in jute or in woven polypropylene bags for selling.

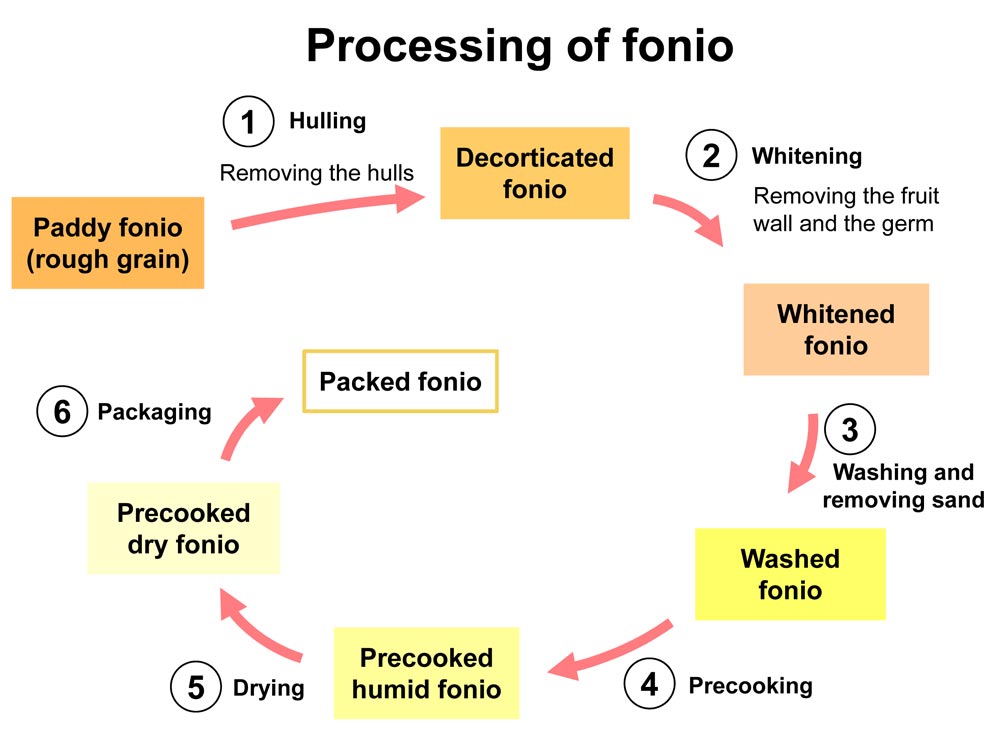

Hulling and whitening

The dried grains are further processed by removing the hulls from the grains (called hulling) and removing the fruit wall and the germ (called whitening). Hulling and whitening require 4 to 5 beatings with pestle and mortar, alternated with winnowing, when done by hand. For mechanical hulling and whitening the GMBF (Guinea-Mali-Burkina-France)-huller was developed by CIRAD, with an output of about 100 kg of grains per hour.

After whitening, the fonio grains must be cleaned to remove the bran and foreign bodies such as sand. Cleaning is traditionally done by repeated washing, which is an extremely time-consuming and tedious operation.

Marketing and organic certification of fonio

Traditionally, fonio is grown for home consumption, especially to provide food during the period of the year before other crops are ready for harvest. So, traditionally only a small percentage of fonio is marketed. In recent years though, the percentage of marketed fonio has increased. Today fonio is sold on many local markets and is traded within West Africa. A very small percentage is traded outside West Africa, some of it being sold as luxury product to Europe and the United States. Locally marketed fonio is mostly sold as hulled fonio. For export mostly precooked fonio is required. Thanks to improvements in post-harvest processing and new market opportunities, the crop has gained new interest among farmers.

Most farmers grow fonio on plots under 1 hectare. In order to meet market requirements and improve profits, farmers have to produce larger quantities. This applies especially to the marketing of commercial fonio.

Cleanliness, an ideal milling degree and a light colour are quality requirements considered to be essential by consumers, and thus strongly determine the price of fonio. These requirements need to be kept in mind when processing fonio.

Precooked fonio is becoming increasingly common and gives higher prices.

Other considerations include:

- Farmers should have sizeable land to produce commercial volumes and to be able to cover the extra costs of certification. To be encouraged to invest in soil fertility management and long-term management, the land should be owned by the producers, or they should have an assured long-term lease on the land.

- Farmers of the same village with adjacent fields can form a producer organisation to minimise the risks of contamination of their crops from neighbouring fields.

- The producers should have access to at least one processing facility (especially for milling and packing), where they can negotiate for preferential treatment of their harvests to minimise contamination with other cereals. For example, during processing, any contamination of the organic fonio from conventionally grown fonio and chemical substances should be avoided. Eventually, as volumes increase, they can acquire their own processing facilities.

- All post-harvest equipment used for handling conventional fonio should be adequately cleaned before being used for organic fonio. It is also very important to use clean bags or containers that have not been used for synthetic fertilisers or any chemicals. Any other reusable bags or containers must be suffi ciently washed before using them for harvested produce.

Comments

Post a Comment