Postharvest handling

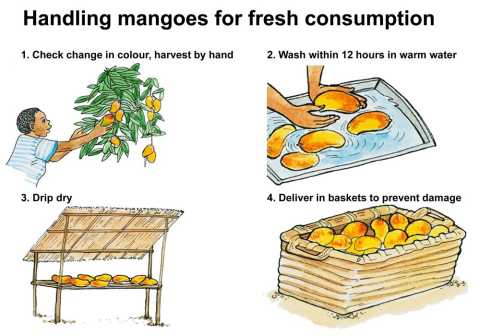

A mango orchard may produce its first marketable harvest after 4 to 5 years, depending on the variety and location. The maturity of the fruit is determined by the changes in colour, fullness of fruit and hardened endocarp (fibrous coating of the seed). The fruit is ready for harvest when the colour changes from green/purple to red/yellow/orange and the inside flesh becomes yellow. Since all the fruit do not ripen at the same time, it is necessary to continuously check the change in fruit colour before harvest.

The mango consumed as fresh fruit is harvested by hand using shears or big scissors. If trees are too high, ladders may be used or a long pole with a cloth bag attached at the tip (that can hold two or three fruit). For fresh fruit sales, the fruit should be put in a crate or a basket lined with some leaves. Fruit for processing can be carried in bags, but avoid putting too much fruit in the bags to prevent damage. Injured or damaged fruit should be separated from healthy ones to avoid possible infection with fungi.

Fresh fruit

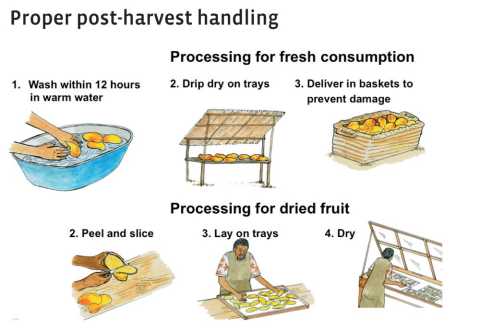

Harvested fruit should be washed immediately—within12 hours—to remove any sap. Generally, if the mangoes are to be sold as fresh fruit, they must be dipped in a hot water bath (55° C, 3 to 5 minutes) to clean them and then slowly cooled to room temperatures. Afterwards, the mangoes should be left to drip dry, sorted and packed in carton boxes or cushioned wooden boxes ready for delivery.

Dried mangoes

In order to avoid wastage, especially during the peak season, farmers may dry the mangoes so that they can safely store them for a longer time. If there is a market opportunity, then they will earn extra income from the dried mangoes.

Drying is based on the fact that microorganisms will not grow when mangoes are dried to a certain moisture level. However, the quality of the dried mangoes will depend on how the process of drying is done. Many technologies for fruit drying are available, depending on the location, ranging from simple plastic tunnel driers to stainless steel cabinet driers. The farmers should contact the local extension officer for guidance. The process of mango drying is, however, done as follows:

- Sorting - After harvesting, the fruit should be sorted to obtain only the fresh, fully ripened and unfermented fruit for drying.

- Washing and peeling - Mangoes should be washed in clean water to remove any dirt and infections on the fruit skin.

- Slicing and drying - The fruit are cut into similar sized pieces and laid out to dry in thin layers on racks, into the dryers at temperatures between 50 and 60° C.

- Sorting and packaging - Before they are packed the fruit are sorted again to remove skin remnants and discoloured fruit.

Marketing and organic certification of mango production

The decision to certify mango production should be based on the possibility to sell to an organic market. This is because certification comes with an added cost which should be payable from the organic mango sales. In order to reduce certification costs, an individual farmer may join an existing or create a new collective certification group.

General requirements for organic certification of mango production:

- During production of mangoes, the use of synthetic pesticides including herbicides and fertilizers, and genetically modified planting materials is not allowed. Any pesticide contamination from neighbouring conventional coffee gardens through soil erosion or wind drift should also be avoided.

- During postharvest handling of mangoes and processing, use of synthetic materials is not allowed, including use of fungicides to protect harvested mangoes from fungal infections.

Specific national or international organic standards define the requirements for production and postharvest handling of mangoes. Farmers should, therefore, consult an organic certification body operating within the region or country for further guidance on certification.

Email: Editor@agricinafrica.com

Comments

Post a Comment