Groundnut Summary Fact Sheet

Production

- 488,300 MT

SRID, 2020

- 85%

- 563,000 MT (2019)

- 565,000 MT (2020)

(Source: MoFA, 2020)

- 337,000 Ha (2019)

- 337,000 Ha (2020)

SRID, 2020

- One cropping cycle (Guinea Savannah and Sudan savannah)

- Two cropping cycles (Forest Zone)

- April (Guinea Savannah: One Season)

- May (Sudan Savannah: One Season)

- April and September (Forest Areas: Two Seasons)

Plant when rains have settled

- 40 cm x 20 cm

- 50 cm x 20 cm (Recommended)

- 125,000 Plants (40 cm x 20 cm)

- 100,000 Plants (50cm x 20cm)

- Inorganic Fertilizer: (NPK 12-30-17 + 0.4 Zn, NPK 15:15:15)

- Organic Fertilizer: (Cow dung, Poultry manure and Compost)

Inorganic Fertilizer

- 5 bags per ha: NPK (NPK 12-30-17 + 0.4 Zn)

- NPK 15:15:15

- Triple Super Phosphate (TSP)

Organic Fertilizer

- Cow dung – 3 tons/ha.

- Poultry manure – 4 tons per ha.

- Compost – 5 tons per ha.

Productivity

- 3.50 MT/Ha (3,500 Kg/Ha)

- 1.63 MT /Ha (1,630 Kg/Ha)

- 1.68 MT/Ha (1,680 Kg/Ha)

SRID 2020

Risks

- 60% Decrease in Yield due to Disease Infestation

- Decrease in Supply

Market & Trade

- GHȼ472.01 (82Kg - Average Wholesale)

- GHȼ560.06 (82 Kg - Average Retail)

- 116 MT

SRID, 2020

Budget Benchmarks

- GHȼ 2,394.53

- GHȼ 7,005.47 (Profit Margins of about 74.5%)

- 42,226 MT

SRID,2020

__

General Overview of Groundnut Production

Groundnuts also known as peanuts are grown in both the northern and southern zones of Ghana. However, it is widely grown in northern Ghana both for home consumption and sale, with women actively involved in the harvesting, processing, and marketing.

Ghana is ranked as the 10th largest producer of groundnuts in the world but consumes most of its produce locally. Perhaps because of the crop’s status as a traditional food grown primarily for the domestic market. Public investment to raise productivity and strengthen the linkage within the value chain, from farmers to end-users, has been relatively limited.

Until recent times, Ghana’s agricultural policy and programmes seems primarily focused on starchy staples such as maize, rice and cassava, or export commodities such as cocoa and oil palm. However, groundnut is amongst the crops under the Planting for Food and Jobs Programme (PFJ) since its inception in 2017. New investments to develop innovative groundnut products in Ghana could offer an unusual opportunity to improve productivity, diet quality and health, through a relatively neglected value chain that links northern low-income groundnut growing households to low-income consumers around the country.

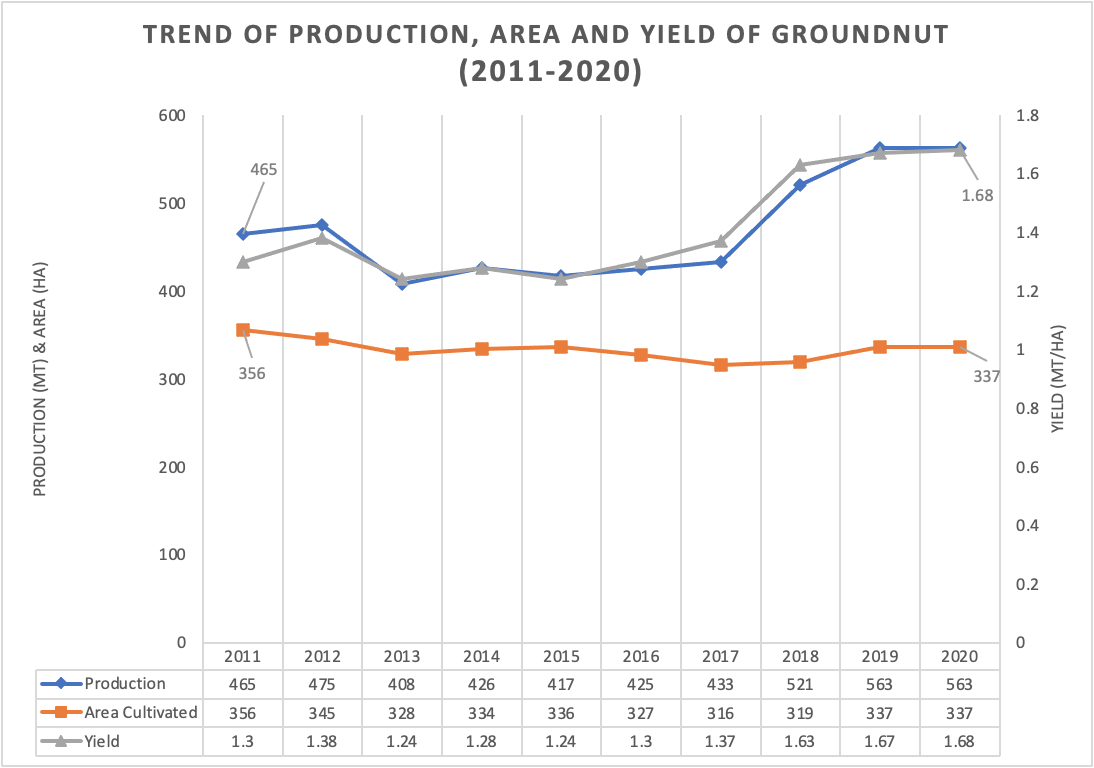

In 2020, the area planted to groundnut nationwide was about 377,000 ha resulting in production output of 565,000 metric tonnes. The average yield on-farm for the commodity under rain-fed conditions is 1.68 Mt/ha but has a potential of 3.5 Mt/ha.

Low yields in groundnut is largely attributed to the usage of poor-quality seeds, poor agronomic practices, and other factors.

Production Trend of Groundnut in Ghana between 2011and 2020

| Year | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

| Annual Production ‘000Mt | 465.10 | 475.10 | 408.80 | 426.63 | 417.20 | 425.83 | 433.77 | 521.03 | 563 | 565 |

| Annual Area Planted ‘000Ha | 356.8 | 345.2 | 328.9 | 334.53 | 336.45 | 327.38 | 316.31 | 319.68 | 337 | 337 |

| Yield (Mt/Ha) | 1.30 | 1.38 | 1.24 | 1.28 | 1.24 | 1.30 | 1.37 | 1.63 | 1.67 | 1.68 |

Research efforts have been intensified by legume breeders at CSIR-SARI and CSIR-CRI to develop varieties for improved productivity. A number of these varieties have been bred to address farmers needs and meet various markets.

__

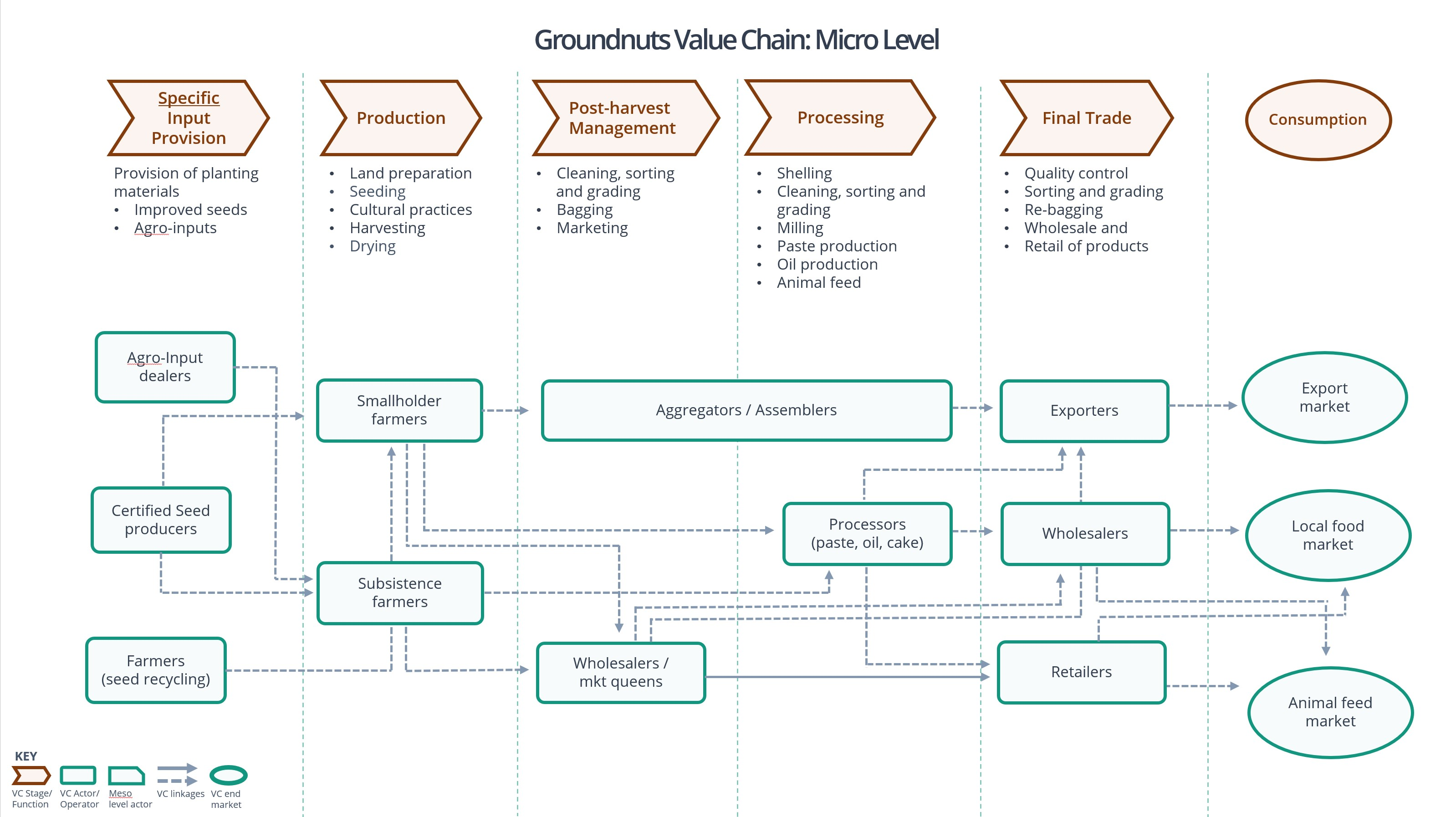

Groundnut Value Chain

Groundnut Value Chain Linkage

Input provision

The groundnut value chain starts with the supply of inputs including seeds, agrochemicals, farm equipment and tractor services. Farmers growing groundnuts have two potential sources of seeds:

- the informal baskets of seeds reserved from their earlier harvest or purchased from neighbouring farmers and through seed exchanges,

- the formal sector selling certified seeds that might be available through local agro-dealers and agricultural supply stores.

Almost all producers use own retained seed or seeds purchased informally in local markets. The resulting seeds are a mixture of improved varieties that have been given local names, sometimes crossed with local seed types.

Groundnut farmers use almost no fertilizers due to their relative cost and lack of access and the natural nitrogen-fixing capabilities of groundnut plants. However, in recent times under the Planting for Food and Jobs Programmes, farmers are given a 50% subsidy on fertilizers and seeds and this has improved the situation.

Except for a few instances where some land preparation and shelling are mechanized, most farm operations are manual. Tractors are used on large holdings, but these are a small fraction of all farms in Ghana.

Production

Groundnut is cultivated by almost all farming communities in the transitional zone and northern Ghana. It is estimated that more than 70% of farmers in the northern part of Ghana cultivate groundnuts and together account for over 85% of the national output. In Ghana, as in the rest of West Africa, groundnut is termed as the woman’s crop due to the major roles women play in its production, marketing, and processing. They function as farmers, traders and in some cases as labourers in planting, harvesting, and shelling. There is an appreciable female involvement compared to other crops like sorghum and rice. The production activities or functions involve land preparation, sowing, and maintenance in the sense of weed control, fertilizer application (in few cases), pests and diseases management, harvesting and finally farm-gate processing or post-harvest management. Primary producers employ hired labourers to carry out activities such as weeding and harvesting of groundnuts. In most cases, family labour is employed in addition to the hired labour to reduce labour cost.

Groundnut is mainly produced under rain-fed conditions and has mainly one cropping season in a year. However, in the transition and some parts of the Upper East Region, particularly in the Kassena-Nankana West District, some farmers can crop twice in a year by taking advantage of dams around. Farm sizes are generally small with an average of 0.8 ha. Harvested nuts are sun-dried for 5-7 days depending on the intensity of the sun. The dried nuts are either sold in the shelled or unshelled depending on the farmer or market.

The potential yield with currently certified seed or improved hybrid materials is 3.5 MT/ha or higher if grown in suitable growing areas with adequate nutrition, moisture, and production methods.

Marketing and Distribution

The groundnut assembling, wholesale as well as retail markets for both dry and processed nuts are dominated by women. Retailers are exclusively women. Though traders operate as individuals, most of them are members of trader-associations. Each bigger market, especially in southern Ghana, has an association for groundnut traders which are often headed by the commodity “queens”. The status and function of the queen is an expression of traditional hierarchies; she establishes informal market rules such as the setting of prices for groundnut and the authorization of new entrants. This is binding on all members of the association.

Dried groundnuts from producing regions are marketed both within and outside the regions. These are either traded at the farm gate, the local market either in community or neighbouring community/town, wholesale market within the district or region or wholesale market outside the region. Apart from acting as intermediary at the market, distributors buy groundnut directly from producers or markets located in production areas and supply to end-users. Rural assemblers within the farming communities purchase from farmers and sell to wholesalers and at times retailers in the cities. At certain times also, several distributors, particularly wholesalers, travel from one community to the other or even sometimes across the boundaries of the country to Burkina Faso to purchase groundnuts themselves. This is usually common during the lean season.

Most of the assemblers use their own money to finance transactions. They can also get cash advances from wholesalers, who play important roles in informal finance in rural and urban areas. Some wholesalers in Accra do not travel to producing centres to buy groundnuts themselves, instead deposit money into the accounts of their agents at the production centres. The agents, in turn, do all the purchases and send groundnuts through transport operators to these wholesalers.

Post-Harvest and Processing

A major influence on the groundnut value chain is how farmers handle the crop after harvest, and how marketed groundnuts enter any off-farm storage and processing before sale to end-users.

Typically, in the Northern Region, harvested groundnuts are laid out on the ground to dry in the open air often left exposed to dirt, dust, vermin, and insects. The best practice is to dry under the unclosed protected area to ensure the quality of the nuts.

Processors, whose scale of operations seems to be concentrated at small scale levels, represent an important sector for women. They process groundnut into oil, cake, paste, roasted groundnuts and other groundnut-based products. Most of the processing takes place at the individual or household level. Some women processors in Techiman (Bono East Region), have received some assistance from Technoserve (an international NGO) and the government to organize themselves into cooperatives. This enables them to take up large orders and maintain continuous supply to institutional buyers and wholesalers from cities like Sunyani, Kumasi and Takoradi.

A certain portion of the kernels kept by the farmers are pressed in the home for the extraction of the vegetable oil which is a major source of income for rural women. The pressed groundnut meal left behind is used as an ingredient in many other dishes prepared in the home.

Trading

Aggregation of groundnut is concentrated in the North of Ghana. Some of the major processing companies of groundnuts are situated in the Northern Regions. Techiman is also a major producing and a transit market for groundnut aggregators, from where they are distributed to Kumasi and to Sekondi-Takoradi and Cape Coast in the coastal regions. Kumasi is another major aggregation and consuming centre of groundnut. Groundnut aggregators also move groundnuts directly from the north to Accra for final consumption and processing.

Retailing of groundnut oil and paste is another function solely undertaken by women. Retailers may trade a combination of paste, oil, roasted groundnuts, or several other commodities. They go to the homes of individual processors or markets for their supplies. Village-level retailers buy processed products from urban processors almost every market day. Depending on the relationship between retailers and processors as well as the financial standing of both parties, some retailers sometimes buy oil/paste on credit and settle their debt after-sales. Research findings indicate that retailers also give cash advances to processors prior to supplies.

Consumption

The Ministry of Food and Agriculture (MoFA) reports show that Ghanaians consume on average 15.83 kg of groundnuts per capita/ year.

Groundnuts serves as a major source of total energy, protein, fat and certain essential vitamins and minerals and are used extensively in many dishes. Roasted groundnuts are eaten as a snack and groundnut butter is used extensively as an ingredient in many dishes such as soup and stews.

Consumption is typically seasonal, as in the north the months of April to July are the season when stored stocks from the previous growing year may be running low and new crops have yet to become available.

According to MoFA’s statistics on the food balance sheet for 2020 production season, the country is currently self-sufficient in groundnut production (see table below). A total of 565,000 Mt of the commodity is produced annually. Out of this figure, about 415,801 Mt (representing 85%) is consumed as food by humans. 10% of the production goes into Seed, Feed and Wastage. Less than 1% (15.80 Mt) is exported.

Food Balance Sheet (2020) Production Season (Groundnut)

| Total Production | 565,000 Mt |

| Human Consumption (food) | 415,801 Mt |

| Total Imports | 0 Mt |

| Carry over stock | 48,996 Mt |

| Exports | 116 Mt |

| Seed, Feed and Wastage | 42,226 Mt |

__

Key Agronomic Practices

Key Agronomic Practices and their Importance

| Good Agricultural Practice | Brief Description and Importance |

|---|---|

Planting Material

| Farmers usually plant late maturing and low yielding varieties. In practice, variety should be selected based on weather information, topography, soil type, ecology, pest/disease resistance and consumer demand. The most suitable variety is the one best meeting farmers’ and consumer’s needs as well as meeting the changing climatic conditions (drought, pest and disease tolerance, earliness, salinity etc.) Common varieties promoted are Obolo, Oboshie, Yenyawoso, Nkateiesari, SARINUT 1&2, Otuhia, Abakan and Chinese. |

| Land Preparation | The objectives of field preparation are based on the following principles: Elimination and control of undesirable plants like crop volunteers and weeds to reduce competition with the established main crop. The land therefore should be cleared, ploughed, and harrowed:

When the soils are heavily infested with perennial weeds like Cynodon or Cyperus, deep ploughing is needed. On land that has been fallowed for two years or more, practice traditional land clearing techniques common in each agro-ecology. |

Choose Suitable Soils

| Groundnuts can be grown on most soils. However, heavy- textured clay soils should be avoided. Areas with high rainfall and high humidity may also be avoided because of high disease incidence. Ideally, well-drained, friable sandy loams are preferred. Choose level land or land with a gentle slope, wherever you decide to cultivate groundnut. Avoid areas with steep slopes, sandy and clayey soils. Choose a deep and well-drained loamy soil for maximum productivity. Sandy soils do not retain water after rain or irrigation and expose plants to drought stress, which can cause total crop failure depending on the crop’s growth stage and duration of the drought. |

| Agro Climate Conditions | Groundnuts are well adapted to a wide range of climatic conditions. For maximum yields and production of a good quality crop, cultivate groundnut in above-ground ecology with an annual rainfall of not less than 550mm and well distributed throughout the growing period. |

Planting

| Planting is the most critical phase in the establishment of a new crop on a prepared field. Some steps to consider before planting includes

Altering planting dates can be used to escape diseases and pest attack. Planting period or cropping calendar differs according to the agro-ecological zone. These cropping calendars are based on the establishment of the rains in each agro-ecological zone. However, farmers experience is the best guide. Experience over the years indicates that planting as early as possible after the rains have established is likely to give the highest yield. Farmers in the Guinea Savannah and Sudan savannah plant once in the cropping cycle around April and May respectively. Farmers in the forest can grow two crops in April and September.

|

Pest and Disease Management

| Pests Pests may damage groundnuts by destroying foliage, sucking plant sap, feeding on roots and pods and transmitting disease organisms. Three main groups of pests attack groundnuts. These are Mites, Millipedes and Insects. All these groups attack either the above ground (leaves or stems) or the underground parts (pods and roots). The foliage feeders are further divided into 2 groups i.e. chewing pests and piercing (sucking) pests. There is no single control method for all the pests that attack groundnuts. Soil pests are more difficult to control than the foliage pests. Some pest control measures for groundnut are detailed below. Cultural control

Natural enemies: There are a few beneficial insects that naturally regulate the population of groundnut pests, e.g. ladybird beetles, hoverflies, lacewings and parasitic wasp. These natural enemies are very susceptible to synthetic insecticides. Use insecticide only when necessary. Diseases Groundnut is affected by several diseases, which can reduce yield by up to 60%. The major diseases are

Yield losses are increased when late and early leaf spots and rusts merge. To control these diseases, spray with fungicide e.g. Benlate, Plant disease resistant varieties, Plant early or alter planting dates, practice crop rotation etc. |

Soil Fertility Management

| The nutritional requirement of a crop is dependent on the variety, soil nutrient content, available moisture, and the level of crop husbandry. As a leguminous crop, groundnut can fix some amount of atmospheric nitrogen. It is also efficient in obtaining nutrients from the soil by exploiting residual fertilizers, especially phosphorus from previous applications. Higher yields will be obtained if some amount of fertilizer especially phosphorous and potassium are applied before planting or shortly after planting. The recommended rate of fertilizer depends on the agro-ecology, soil type, cropping history of the field and soil nutrient test.

|

Weed Management

| Weeds act as hosts for pests and reduce both yield and quality of the nut. In addition, fodder yield may also be reduced since groundnut is not a strong competitor for resources, particularly at the establishment stage. In other words, groundnut should be kept free of weeds after establishment. When fields are left unweeded, groundnut can be completely smothered by weeds resulting in total yield loss. Weeds compete with the crop, during growth, for light, water, and nutrients. Weeds can cause greater yield reduction than arthropods, bacteria, viruses and fungi disease attacks and may lower quality of the produce. Control weeds early, especially during the first six weeks after planting. Good land preparation helps in controlling weeds and gives groundnut a starting growth advantage over weeds. Recommended herbicides can also be employed in checking weeds. An alternative to manual weed control is to practice no-tillage. |

Irrigation

| Irrigation is helpful in maintaining yield and quality when natural rainfall is inadequate, especially, during the peg and pod filling period. Irrigated fields should have a good weed and disease control programme to prevent excessive losses in yield and quality. There are three major stages in the life cycle when moisture stress can cause a significant reduction in the quantity or quality of groundnuts produced:

Water according to needs dictated by the growing conditions. The actual amount and frequency of water required will depend on the growth stage of the plant, soil type, and predominant weather conditions (temperature, rainfall, wind speed and relative humidity). Do not wait until drought symptoms occur to irrigate. This will result in loss of yield and delay maturity ultimately reducing quality. It is also best to maintain adequate soil moisture during the fruiting period. Drought during this period can often lead to a split crop that makes harvest and crop management more difficult and expensive. |

Cropping Systems

| Intercropping Most farmers intercrop ground nuts with cereal such as sorghum, millet and maize. It is also intercropped, with yams and cassava. Advantages of intercropping includes:

The groundnut population may vary considerably depending on the importance a farmer attaches to the companion crop. Spatial arrangements, population density and suitable varieties for inter-cropping are yet to be established in Ghana. Crop Rotation Groundnut should not be cultivated on the same piece of land for successive years. It should be included in crop rotation. Rotation helps to control pests and diseases, e.g. Nematodes, mould, leaf spot, etc. It is recommended that crops which are susceptible to infestation by the same pests and diseases should not succeed one another in rotation. |

Harvest Management

| The groundnut plant usually gives an indication of when to harvest. They should be harvested when approximately 75 % of the pods have reached the maturity; that is when the leaves turn to yellow colour and dry at the tips. At the same time, the soil desiccates to such an extent that the plant withers and the seeds in the pods begin to shrivel and take on a ripe appearance. Loosen the soil around the plants with a spade or garden fork before harvesting groundnuts. Generally, groundnuts are harvested by pulling/digging out the whole plant with nuts attached. It is shaken to get rid of the excess soil from the roots, still leaving the pods attached. Check the soil to make sure you are not leaving any pods behind. Premature or delayed harvesting will affect oil content, aflatoxin incidence and fungal infection. The conventional method of determining maturity is by randomly digging a few plants and assessing pod-fill by pressing and cracking nuts. The inside wall of matured pods are usually dark brown. |

Post-Harvest practices

| Drying and Sorting After the harvest, groundnuts pods are dried on the sun. The dried harvested nuts may be left for a few weeks either on the farm or in the homestead. Dried nuts move freely inside pods when shaken. They are later threshed and winnowed. The groundnuts are also sorted. Sorting aims at separating fully filled grains and unfilled or damaged ones and stored. Storage Pods provide protection for the groundnut seeds and allow their storage for long periods without significant loss of viability. Dried groundnuts can be stored in sacks, clay/mud silos, large woven straw baskets, clay pots, etc. until needed. Shelling Shell groundnuts when needed. For seed, shell groundnuts a few days to planting. Shelling can be done by Hand (cracking) or Machine (decorticators). Processing/Uses of Groundnut Groundnuts is a source of protein and oil. It contains about 21-25% protein and about 45% oil. Groundnuts can be eaten boiled/ roasted, processed into oil for cooking or a paste for soups and spreads. They are also used in the confectionery industry as groundnuts are processed into various products such as cooking oil, groundnut butter etc. |

__

Key Risks Along the Value Chain and Mitigation Measures

| Value Chain Actions | Key Risks and Challenges | Mitigation Measures |

| Input Supply | Seed quality and variety types affecting productivity | - Use improved and certified seeds and agro-input for production - Training on Good agricultural Practices |

| Finance | Inadequate credit and unsuitable financing mechanisms to support existing and prospective farmers | Provision of incentives Interest subsidies for actors |

| Production | Climate Change (Erratic rainfall patterns)

| Cultivate early maturing varieties Use drought-tolerant varieties Pay attention to early warning systems and plant when the rains have stabilized Cultivate in valley bottoms |

| Soil infertility affecting yields | Carry out soil test before production Apply recommended and appropriate fertilizers where appropriate Train farmer in the management of soil nutrition | |

Pests and diseases attack

| Pay attention to early warning systems Apply recommended agro-chemicals Use pests and disease tolerant recommended varieties | |

| Post-harvest handling | High post-harvest losses and wastages Aflatoxin infestation Rancidity

| - Practice good harvesting and handling management - Improved (enclosed) transport means - Training on processing and product diversity and utilization - Drying to acceptable moisture content level |

| Inadequate post-harvest infrastructure | Install storage facilities in high growing areas | |

| Marketing | The volatility of market prices

| - Establish strong B2B linkages between producers, processors, and industrial consumers. - Market information be made accessible to the public and value chain actors |

| Processing | High-level traditional processing methods for threshing leading to low outputs | Use improved processing technology (mechanical threshers) |

| Consumption | Limited varieties meeting diverse consumer preference | Develop demand-driven groundnut varieties |

__

Pests & Diseases, Symptoms and Control Measures

Major Pests and their Control Measures

| Pest | Symptoms | Management/Control Measure |

|---|---|---|

Thrips: (Scirtothrips dorsalis, Thrips palmi)  This small insect lives in the flowers and folded leaflets of groundnut. They are pale cream in colour and are usually hidden. They are numerous in the post-rainy season |

|

|

Leaf miner (Aproaerema modicella)  Leaf miners are the larvae of various beetles, flies, moths, and sawflies. The adult lays their eggs on the leaf and the larvae burrow into the leaf and tunnel through it, feeding and leaving a transparent trail of where they have been |

|

|

Termite  Termites primarily feed on wood, but some species collect green grasses and seeds and store these in their granaries inside their nest as food reserves. They are sporadic pests, and locally are important on a wide range of crops |

|

|

Millipedes (Peridontopyge spp.)  Millipedes are among the economically important soil pest of groundnuts. They are brown to blackish in color and curl when disturbed. They attack groundnut seedlings, between planting and approximately 20 days after planting, feeding on the emerging cotyledons and moving to the root system at the collar region. |

|

|

Rodent and Birds  Rodents [especially rats, squirrel, mice, and wild rabbits] can cause serious damage by eating the seedlings early in the season. Birds [partridges, crows, etc. also pick seed after planting. |

|

Major Diseases and their Control Measure

| Diseases | Symptoms | Management/ Control |

Cercospora arachidicola  This is a fungal ascomycete plant pathogen that causes early leaf spot of groundnut |

|

|

Groundnut Rosette Virus (GRV)  This is a groundnut pathogenic virus found in Sub-Saharan Africa. It is transmitted between plants by insect vectors such as the ground aphid (Aphis craccivora). |

|

|

Other Major Diseases of Groundnuts - Symptoms and Control Measures in Ghana

| Disease | Symptoms | Time of Occurrence | Control measures |

| Rust | Rust-like spots (dead spots) on leaves | 4-13weeks after planting but prominent at the padding | Fungicide e.g.

|

| Peanut clump | Dwarfism | Seedling stage |

|

| Groundnut mold | Seeds become moldy | Before harvest During storage Processing |

|

| Stem and pod rot | Wilting of lateral branches, leaves become chlorotic and turn brown | All stages of growth |

|

__

Market Information on Groundnut

The major markets for trade and commerce of groundnut includes Northern, Upper East, Upper West, regions and parts of Brong Ahafo Region.

A variety of grain trading companies have practiced spot buying of groundnuts in the past, particularly Ghana Nuts Company in Techiman. They have typically done so through private aggregators. One private trader/aggregator who served this market is BASA Agribusiness in Tamale, who supplied groundnuts to Ghana Nuts on a commission basis, working with 62 agents who have their own farmers in the various districts that they buy from. BASA Agribusiness used funds advanced to him from Ghana Nuts to pre-finance his agents so they could do the spot transactions. The firm was able to supply high volumes of groundnuts to Ghana Nuts until Ghana Nuts encountered problems of aflatoxin, because of inadequate drying before storage.

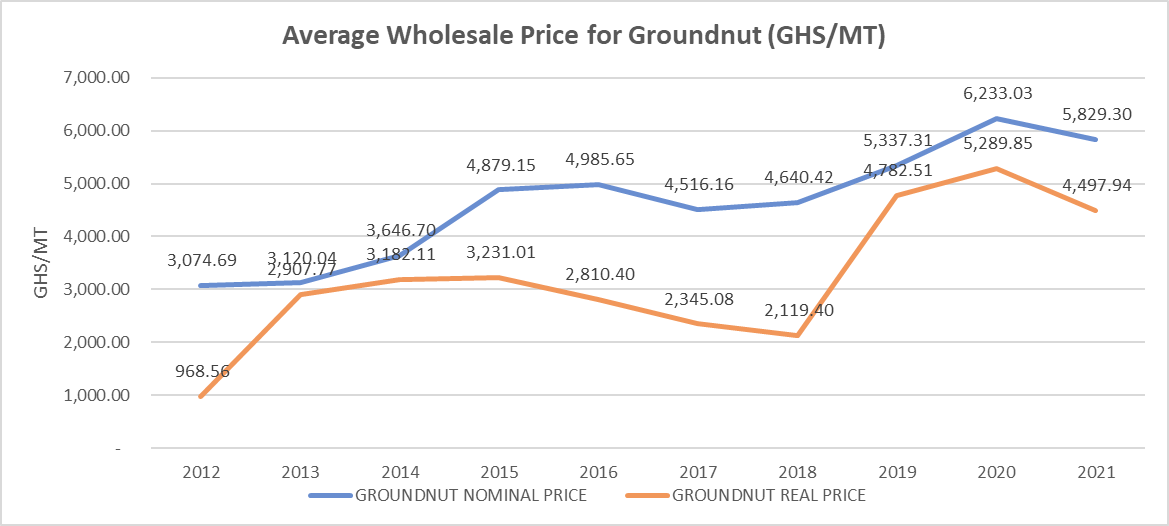

Price Trends

The Ghana National annual average nominal wholesale market price for a ton of Maize as at 2021 was GHS5,829.30 whiles the annual real price was GHS4,497.94.

The Ghana National average wholesale market price per bag (82 kg) of Groundnut as at 2020 was GHS 623, decreased to GHS583 in 2021.

Average Wholesale Price for Groundnut(2012-2021)

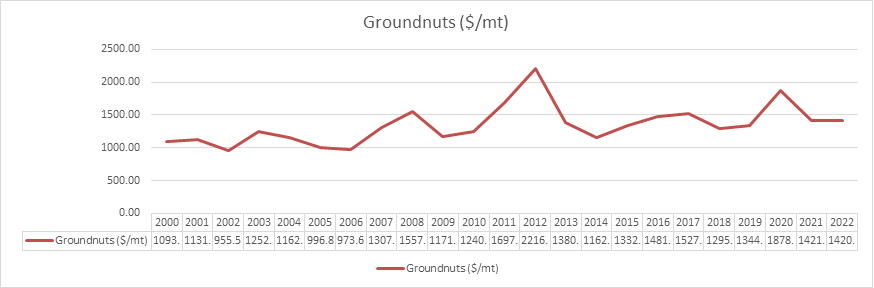

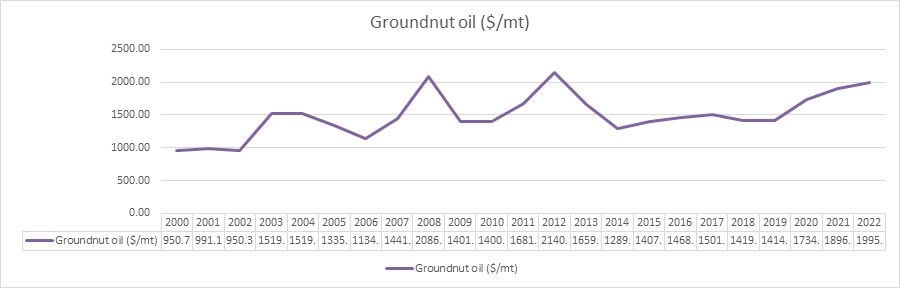

World Prices for Groundnut and Ground oil 2000- 2022

__

Enterprise Budget for Groundnut

Production of One Hectare Groundnut under Rain-Fed Condition - Average yield of 2 Mt/ha (2019)

No. Activity Cost per Hectare (GH¢) Rain-Fed Qty. / Freq. Unit cost (GHȼ) Total cost (GHȼ) 1 Land preparation Ploughing 1 200.00 200.00 Harrowing 1 100.00 100.00 2 Crop establishment Certified seed 40kg 7.00 280.00 Planting 1 ha 250.00 250.00 3 Weed management Pre-emergence herbicide 2.5 lts 35.00 87.50 Application cost 1 ha 50.00 50.00 Weeding with Hoe (2 times) 1 ha 200.00 200.00 4 Fertilizer management SSP/TSP/NPK 5 120 600.00 Application cost 1 50 50.00 5 Harvest 1 ha 200.00 200.00 6 Threshing 1 ha 200.00 200.00 7 Bagging 20 bags 1.00 20.00 8 Empty sacks 20 2.00 40.00 9 Sewing twine 2 rolls 1.50 3.00 Production cost 2,280.50 5% Contingency 114.025 Total Production Cost 2,394.53 (A) Total Revenue 20 bags/ha GHȼ 470 per 82 kg 9,400.00 (B) Net revenue (A-B) 7,005.47

| No. | Activity | Cost per Hectare (GH¢) Rain-Fed | |||

| Qty. / Freq. | Unit cost (GHȼ) | Total cost (GHȼ) | |||

| 1 | Land preparation | Ploughing | 1 | 200.00 | 200.00 |

| Harrowing | 1 | 100.00 | 100.00 | ||

| 2 | Crop establishment | Certified seed | 40kg | 7.00 | 280.00 |

| Planting | 1 ha | 250.00 | 250.00 | ||

| 3 | Weed management | Pre-emergence herbicide | 2.5 lts | 35.00 | 87.50 |

| Application cost | 1 ha | 50.00 | 50.00 | ||

| Weeding with Hoe (2 times) | 1 ha | 200.00 | 200.00 | ||

| 4 | Fertilizer management | SSP/TSP/NPK | 5 | 120 | 600.00 |

| Application cost | 1 | 50 | 50.00 | ||

| 5 | Harvest | 1 ha | 200.00 | 200.00 | |

| 6 | Threshing | 1 ha | 200.00 | 200.00 | |

| 7 | Bagging | 20 bags | 1.00 | 20.00 | |

| 8 | Empty sacks | 20 | 2.00 | 40.00 | |

| 9 | Sewing twine | 2 rolls | 1.50 | 3.00 | |

| Production cost | 2,280.50 | ||||

| 5% Contingency | 114.025 | ||||

| Total Production Cost | 2,394.53 (A) | ||||

| Total Revenue | 20 bags/ha | GHȼ 470 per 82 kg | 9,400.00 (B) | ||

| Net revenue (A-B) | 7,005.47 | ||||

Key Policies and Programmes

Policy Environment and Regulations

Constraints for peanut value chain in Ghana include inadequate rural infrastructure and public services required by actors in the low-income Northern Region.

Government regulations and interventions that could potentially impact peanut farming include:

- National Irrigation Policy, Strategies and Regulatory Measures, June 2010

- Guidelines for National Plant Protection Policy, June 2004

- National Water Policy, June 2007

- Environmental Protection Agency Act, 1994 (Act 490)

- Environmental Assessment Regulations, 1999, LI 1652 and its Amendment

- Plants and Fertilizer Act, 2010 (Act 803)

- Water Resources Commission Act, 1996 (Act 522)

- Food and Drugs Act1992, PNDCL 3058

- Irrigation Development Authority Act, 1977, SMCD 85

- World Bank Safeguard Policy on Pest Management, OP 4.09

- USAID Requirements on Pesticide Management

Regulatory practices can change at any time, however, so any specific new venture should be preceded by appropriate due diligence regarding any potential regulations that might apply to it.

Quality Standards for Aflatoxin

The Ghana Standards Authority (GSA) publishes the Ghana Standards Gazette that has specifications for groundnuts (GS 313:2001), code of practice for prevention and reduction of aflatoxin contamination in groundnuts (GS 1003:2009), and the determination of aflatoxins in foodstuffs (GS ISO 16050:2003).

Programmes

The different number of programmes and projects were fashioned to run and or are still running to support the growth of the grains industry in Ghana.

Projects and Programmes and their Outputs

| Project/Programme | Duration | Activities/Output |

|---|---|---|

| West Africa Agricultural Productivity Programme | 2013-2018 | Supported groundnut research and seed production in Ghana |

| Ghana Grains Development Project | 1979–1997 | Standardising pricing policy to promote competitiveness in the grain industry of Ghana. |

| Food Crops Development Project | 2000–2008 | To enable beneficiaries, raise their household incomes and improve overall nutritional status and standard of living through increased production, processing and marketing of farm produce. |

| National Food Buffer Stock Company (NAFCO) | 2010 to present | Established in insulating farmers from the glut on the market that usually resulted from improved production levels |

| Planting for Food and Jobs (PFJ) campaign | 2017 to present | Seeks to increase agriculture productivity and catalyse a structural transformation in the economy through increased farm incomes and job creation. Motivate farmers to adopt certified seeds and fertilisers through a private sector-led marketing framework to raise the incentives and complimentary service provisions on the usage of inputs, good agronomic practices, and marketing of outputs over an e-agriculture platform |

Comments

Post a Comment