Mango Summary Fact Sheet

Production

- 8,000

- 99,242 MT (2020).

FAOSTAT, 2020

- Brong Ahafo 8,685 acres

- Northern 8,187 acres

- Eastern 5,510 acres

- Volta 4,837 acres

- Greater Accra 3,453 acres

- Ashanti 1,000 acres

Southern Zone

- Major season: May-August

- Minor season: December-February

Northern Zone

- Mid-April and Mid-August

- Mexico, India, Thailand, Brazil, Mali, Burkina Faso, Cote D’Ivoire and Senegal

- Blue Skies, HPW Fresh & Dry Limited, Bomarts Farms Limited, Pinora, and Peelco

- The crop is cultivated year-round

- At least 2 months of dry period is required for flower induction

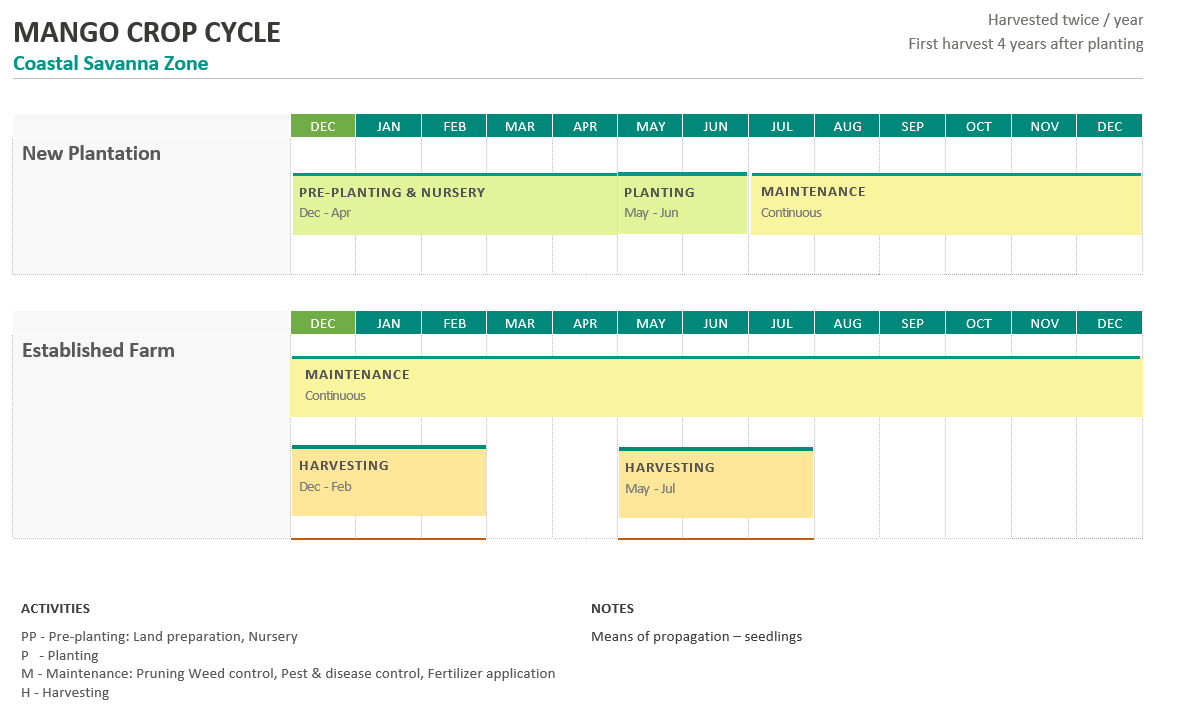

- Mango tree starts bearing fruit 3 years after planting

- Economic bearing stage is 7 years

- Plant just before rains: April – May and August - September (May be different under irrigated mango farm and location).

- 10m x 10m.

- 9m x 6m

- 8m x 8m

*Depends on location and cultivars. For intensive management some recommendations include: 6m x 6m, 8m x 6m, 9m x 6m, 10m x 5m

- 100 trees

- 140 trees

- 160 trees

*124 to 140 for 9m by 9m spacing.

*100 trees per acre at ITFC (irrigated)

- Urea – 8 bag (400kg)

- Sulphate of Potassium – 8 bags (400kg)

- NPK 15:15:15 - 5 bags (250kg)

An acre of 24,000 plants:

- Urea – 1/2 bag (25kg)

- Sulphate of Potassium – 2 bags (100kg)

- Use 1,200 litres of water.

- For a drum of water (i.e. 200 litres) mix 4.4kg of urea and 8.2kg of SOP and apply it to 4,000 plants

- Repeat application (2.5 times) to meet requirement per hectare

- Between 2,000 Mt and 5,000 Mt

- Coastal Savannah

- Forest Savannah and Transition and

- Districts in the Eastern Region

- Demand for count 8 and 10 or smaller size 12 per 4 kg

- Brazil: September-February

- Cote d’Ivoire: March – July

- South Africa: Dec-May

- USA: March to November

- Mexico: May – November

- Venezuela: March – Sept

- Ghana: May-July and Dec – Feb

- Mali – March - June

- Peru: December-April

- Cut fruits,

- Dry mangoes

- Juice

- November and December targeting the winter (January and February) market in Europe

- March and April targeting the local processing floors

- 8,000 Ha

SRID,2020

- Average yield: 7.5 – 12.5 MT

- Potential Yield: 25 MT

Crop Directorate, 2021

Risks

- Land Acquisition,

- Bacterial BlackSpot,

- Over-reliance on natural rainfall,

- Lack of facilities for packing and

- Lack of skilled workforce

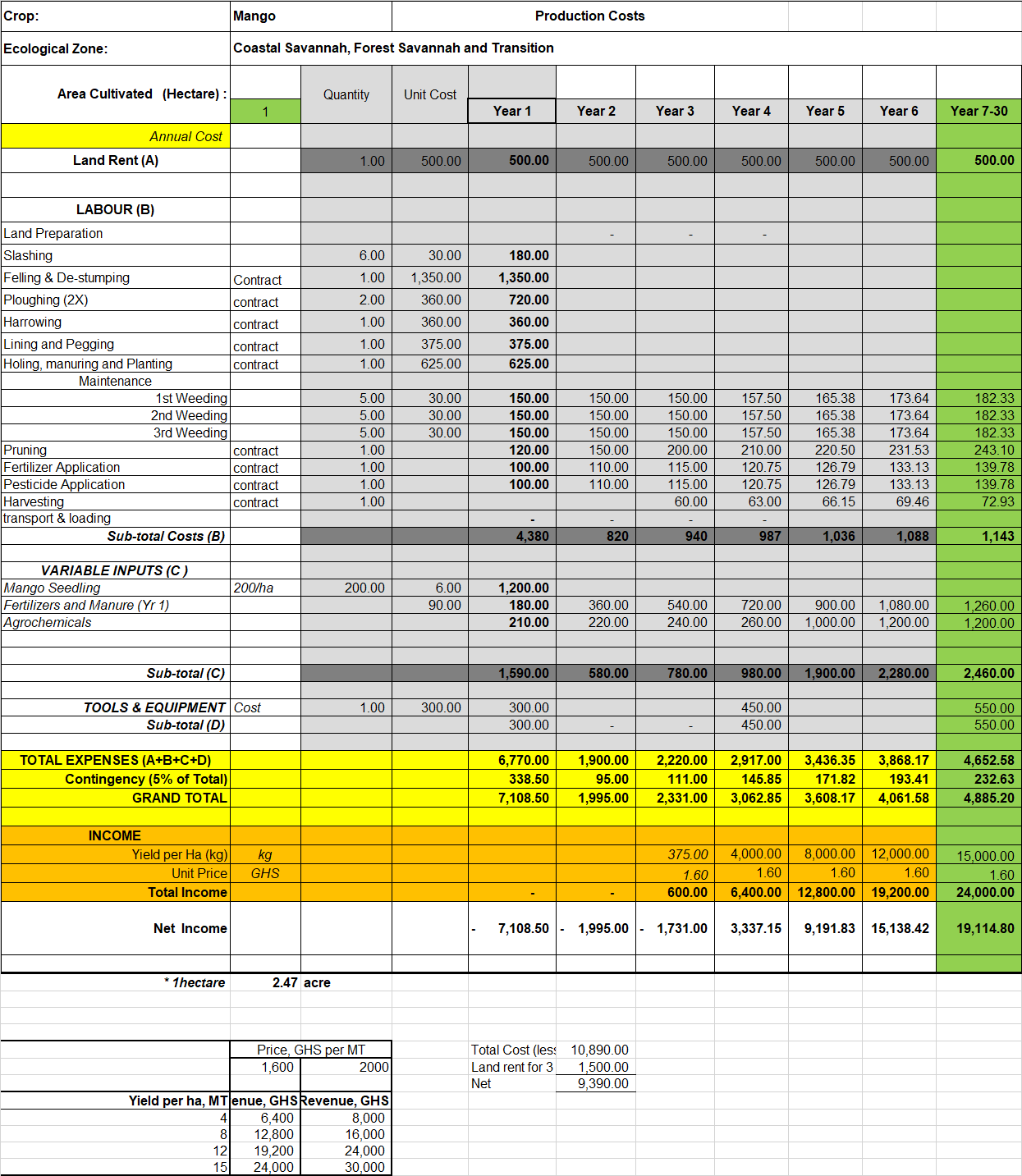

Budget Benchmarks

- $ 6.59 to $ 7.26 per Kg

- GHS 42.12 per kg

___

General Overview of Mango Production

Mango (Mangifera indica L) has been referred to as the “king” of fruits on account of its taste, aroma and food values. Mango is a member of the Anacardicaeae family and was introduced in Ghana by Portuguese missionaries. They grew turpentine and Jaffna mango cultivars (Ceylon) at their abodes. The exotic cultivars namely Keitt, Kent, Haden, Atkins and Palmer are now the most popular export mangoes introduced from Florida nearly 40 years ago.

Compared to other West African origins, the presence of fresh mangoes from Ghana on international markets is relatively modest (amounting to less than 3% of EU import volumes supplied from ECOWAS countries). Export volumes to EU increased from 3649 tonnes in 2020 to 4708 in 2021.

The Global demand for Mangoes has seen a steady growth from USD 2.91billion in 2017 to USD 4.14billion in 2021. • The USA was the biggest importer of Mangoes at a value of USD 818.2m. Other prominent global importers were China (USD 774.78m), Netherlands (USD 376m), Germany (USD243.4m, UK (USD 230. 1m) and France (USD155.8m).

The major growing countries are Mexico, India, Thailand and Brazil and in West Africa, we have Mali, Burkina Faso, Cote d’Ivoire and Senegal. Global exports of mangoes, guavas and mangosteens rose to 2.2 million tonnes in 2020, an increase of 2.9 percent from 2019. Global exports of mangoes, guavas and mangosteens rose to approximately 2.2 million tonnes in 2020, an increase of 2.9 percent, or some 60 000 tonnes, from 2019.

In Ghana, mango exports have increased during the implementation period of USAID's Trade and Investment Program for a Competitive Economy (TIPCEE) between 2005 to 2008/09. Total mangoes produced reached over 131,600 MT in 2020. There are a number of processing companies undertaking fresh cuts (Blue Skies) and dry fruits (Bomarts Farms, HPW) for the export market. The processing companies also import mangoes from other production sites outside the country when the fruits are out of season.

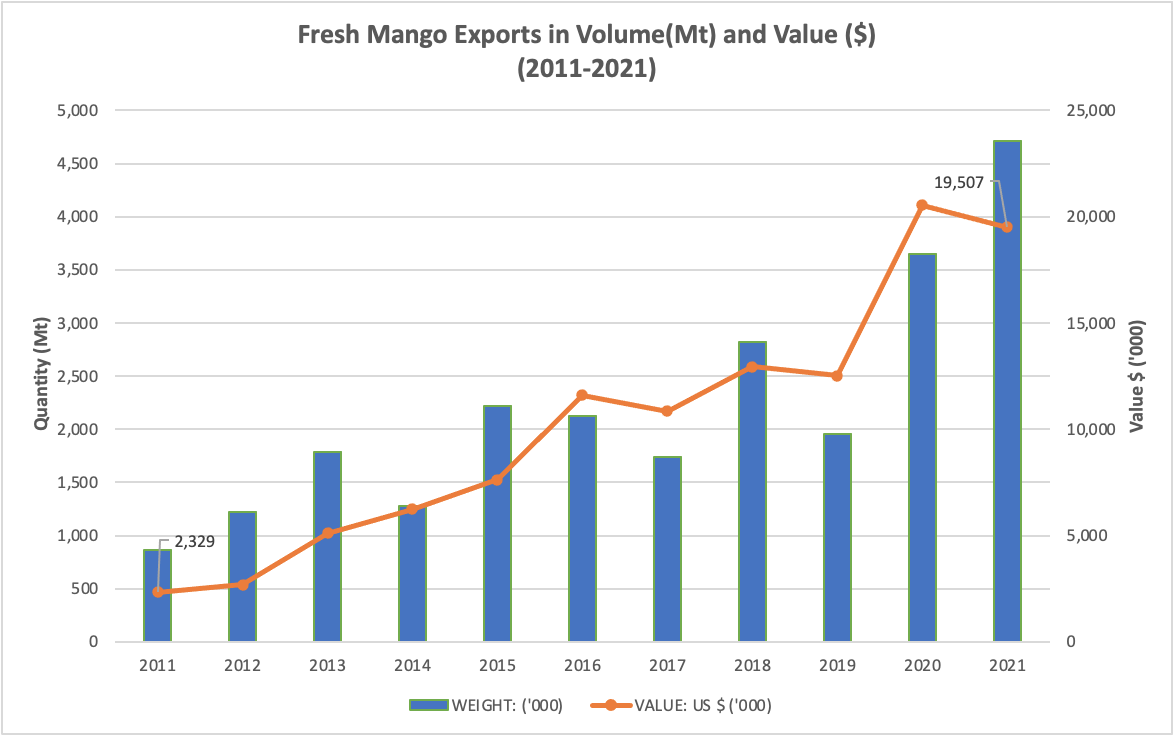

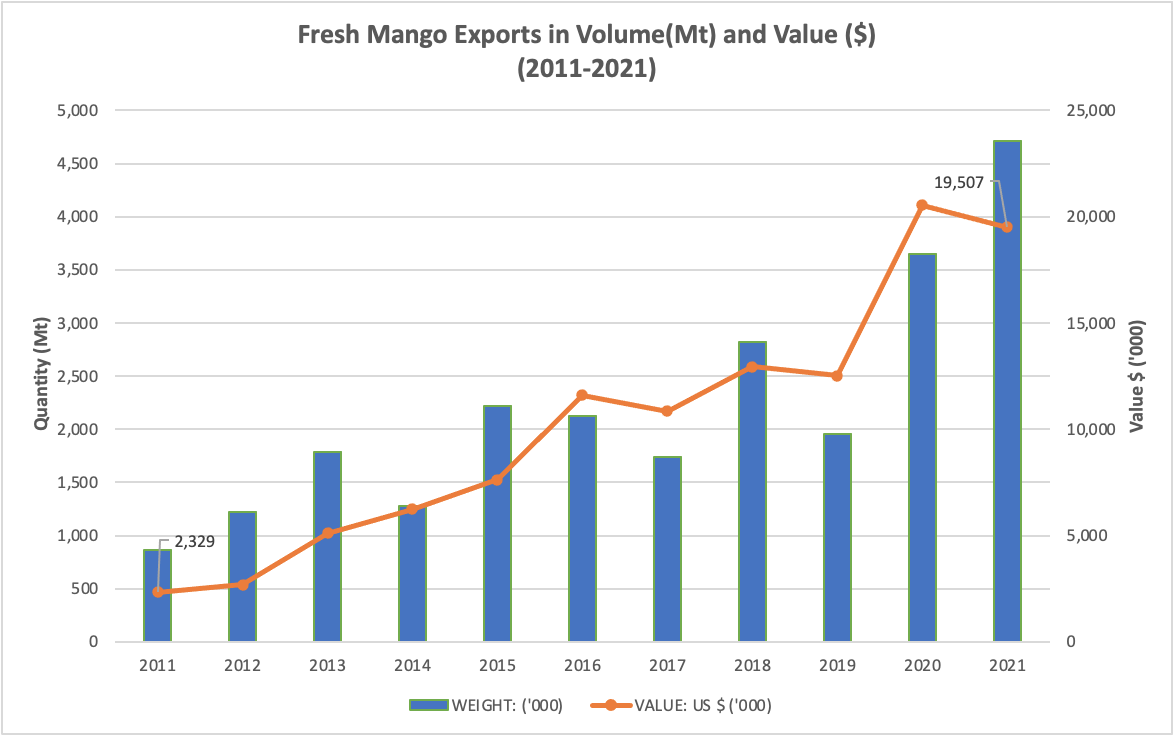

Export of mangoes from Ghana to EU, increased significantly from 868 MT valued at $2.3 million in 2011 to 4,708 MT valued at $19.5 million in 2021. representing over 1,000%. This has decreased slightly to 1,741 MT valued at $10.85 million in 2017 on account of better prices and exchange rate fluctuations.

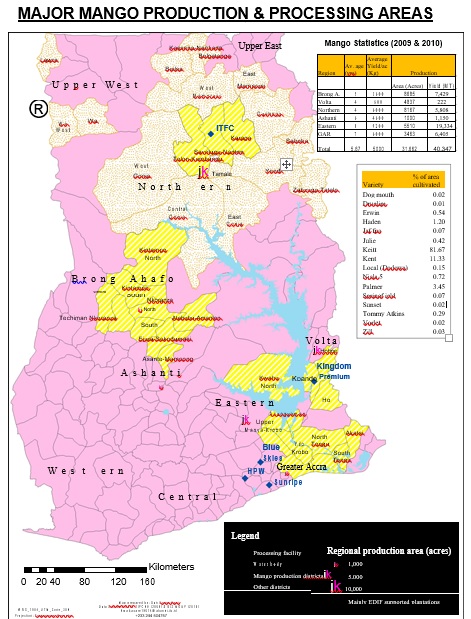

Mango farming zones depicting acreages and variety under cultivation and value-added actors at various location across Ghana is shown below.

Figure 1: Fresh Mango Exports in volumes, MT and value, $, (2011 to 2021)

Surprisingly, there is a demand gap and processing industries import between 2,000MT and 5,000MT annually into Ghana and mostly from West Africa neighbours and Brazil.

The major ecological zones for mango production are Coastal Savannah, Forest Savannah and Transition and specifically in these districts in the Eastern Region- Yilo Krobo, Asuogyaman, Dangme West, Manya Krobo and Akwapim South; Other growing areas are Bono and Bono East regions: Techiman, Wenchi, Kintampo, Nkoranza and Atebubu; Volta Region: Tongu, Kpando, Hohoe, Ho; and Northern Region: Tolon, Kumbungu, Savelugu, Nanton and Mamprusi.

There are over 8,000 mango farmers in Ghana in many producer associations and outgrowers in various district .

| Type of Mango | Producing Countries | Characteristics |

Keitt.

| Ghana, Colombia, Costa Rica, Kenya, Israel, Egypt, Ivory Coast, South Africa, Zimbabwe, Uganda,Peru, Dominican Republic |  The trees are vigorous growers, but tend not to reach heights much over 20 feet. It has a low spreading habit that is not as compact as most other mango trees, and develops an open canopy. Fruit production is relatively heavy and consistent. Unlike most mango species, Keitts don’t have fibrous pieces in their flesh. This creamy, sweet fruit is excellent for desserts, salads, smoothies and preserves. Depending on the conditions, this tree will usually reach between 3 and 5 metres in height, with a spread of 2 to 4 metres. For smaller areas, you can prune it down so that it doesn’t become too large. |

Kent

| Ghana,Ecuador,Egypt, Morocco,Israel, Mexico, South Africa, Venezuela, Puerto Rico, Gambia, Ivory Coast, Costa Rica

|  Kent mangoes are large, oval fruit with dark green skins, sometimes with a dark red blush. They have juicy, tender golden flesh with few fibers, which makes them excellent for juicing. it has an average weight between 200 -250 grams.

|

Atkins

| Ghana, Morocco,Israel, Mexico, South Africa, Venezuela, Puerto Rico, Gambia, Ivory Coast, Costa Rica, Zimbabwe, Jamaica, Guatemala |  A Floridan variety with medium to large fruits (450-700 g), ovoid in shape, with a rounded apex. Green-red coloration, numerous large green-yellow lenticels. Firm orange juicy flesh, containing fibres |

Haden

| Mexico, Ecuador, Peru, Ghana

|  This variety is bred from a sowing of ‘Mulgoba’ in 1902. The fruit has fine appearance and a reputation for fragility, requiring rapid sale. it has an average weight between 510 and 680g. Orangey yellow, almost fibreless. Pleasant, slightly acidulated taste. Oval to rounded cordate. the ventral shoulder is broader and slightly higher than the dorsal shoulder. well-rounded apex. |

Palmer

| Brazil, South Africa, Ghana | The fruit is large, with especially big specimens reaching several pounds in weight. Coloration tends to be yellow with red blush when ripe; the fruit will turn purple long before becoming mature, sometimes leading to immature fruits being picked. The flesh is orange-yellow and has a mild and aromatic flavor, with minimal fiber

|

S.W.O.T Analysis of Mango

Strength

| Weakness

|

Opportunity

| Threats

|

___

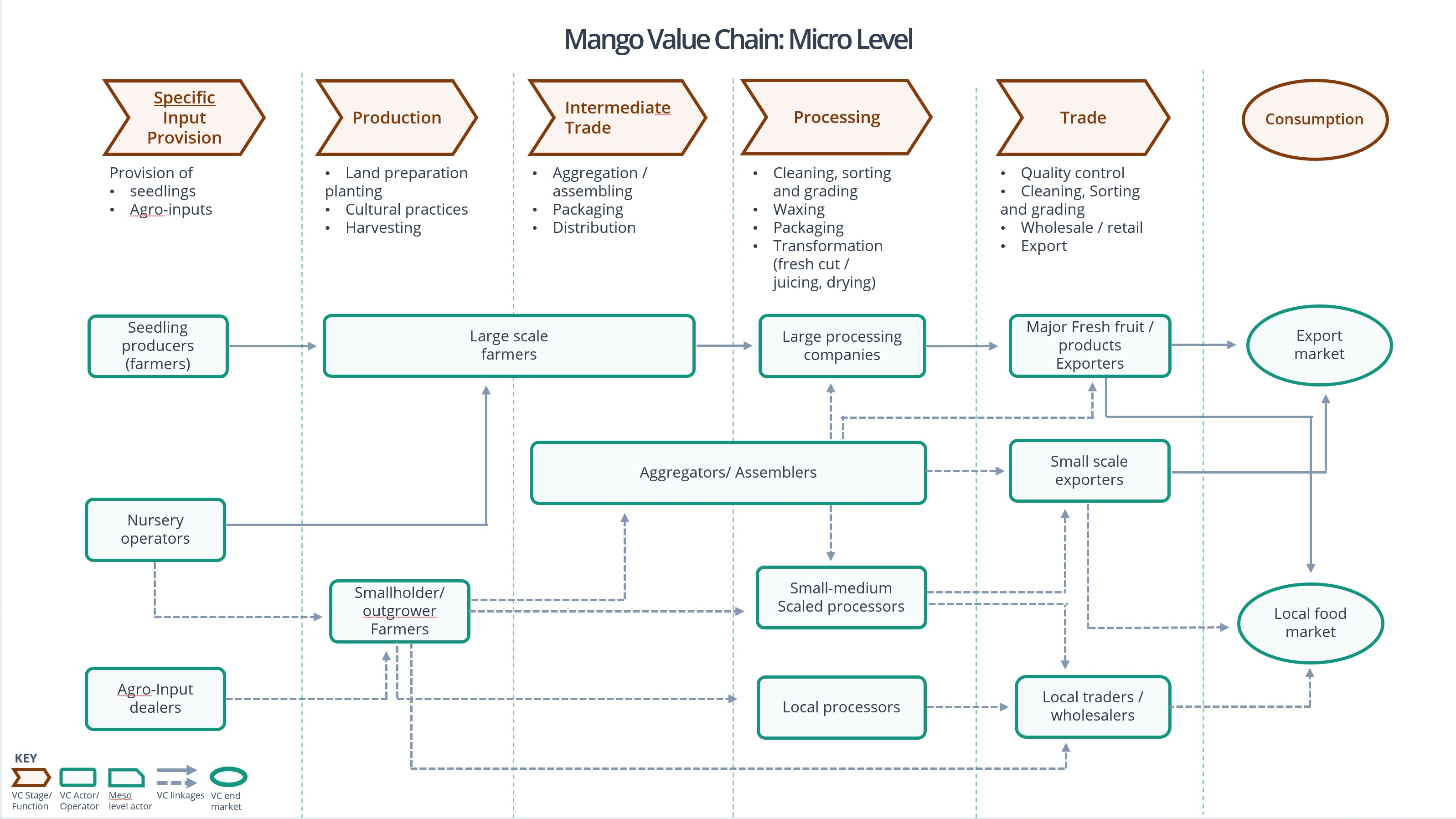

Mango Value Chain

Input Dealers

Within the Greater Accra-Tema Metropolis are located large-scale input dealers. The SME input dealers are located and available in all the growing areas. They offer for sale to mango producers a range of farm inputs including seeds/seedlings, budding/Grafting knives, agrochemicals (fertilizers, pesticides), irrigation equipment, spraying equipment, shade net and compost. Additionally, the input dealers provide extension services to back sales on location.

Some of the input supply chain actors are mango nursery operators, agrochemical dealers such as Agrimat, Sidalco, Aglow and other smaller retailers dotted in and around the mango growing areas.

Commercial Nursery Operators

Commercial nursery actors who have been trained and certified by MoFA and GIZ abound within the value chain. Mango seedlings are raised as part of farm operations near permanent water sources close to producers undertaking rain-fed cultivation and on location by producers with access to irrigation on large scale operations.

Mechanization Service Providers

Within the value chain, the SMEs depend on private Mechanization Service Providers to undertake land preparation services including stumping, ploughing and harrowing. On the large-scale farms, such services are routinely provided by in- house company workers.

Farmers/Producers

Mango production within the Southern Horticulture Zone (SHZ) is dominated by an army of SME producers who belong to various production associations. The Somanya based Farmer Based Organisation (FBO), Yilo Krobo Mango Famers, is the most organized with membership strength of 250. The Dodowa based Dangbe West Farmers has a membership strength of 80 members whilst VOMAGA with 69 members are located in the Lower Volta basin at Juapong and Fojuku respectively. Farm Management Services Limited (FMSL), a Somanya based Plantation Development and Management Services Provider, belongs to Yilo Krobo Mango Farmers Association with main 6 clients including Cotton Web Link Farms, Premier Exotic, UAM, SMI, Beulah and Kwesnah. FMSL operates a total of 1,130 hectares of mango of which Cotton Web Link Farms owns about 500 hectares as of 2011. Another large mango estate within the SHZ belongs to Bomarts Farms located in the Volta Region.

The Middle belt production is driven by the following producer associations who drive the mango expansion envisioned for the belt.

| Name of FBO | Location | Membership Strength |

| DAMFA (Dangme-West Mango Farmers Association) | Dangme-West | 100 |

SGF (Sunyani Greenfield Co-operative and Mango Producers and Marketing Society Limited | Sunyani and Berekum | 65 |

| Yilo Krobo Mango Farmers Association | Yilo Krobo | 368 |

| Kintampo North Mango Farmers Association | Kintampo | 56 |

| Kintampo South Mango Farmers Association | Jema | 54 |

| Wenchi Mango Farmers Association | Wenchi | 48 |

| Atebubu Mango Farmers Association | Atebubu | 30 |

| Techiman Mango Farmers Association | Techiman | 50 |

Preferable varieties are

- Keitt and

- Kent

Processors

Processing for export

Six major processing companies are involved in fresh pre-cuts, dried and fruit juice products that are exported mainly to the EU market. These include Blue Skies, HPW Fresh & Dry Limited, Bomarts Farms Limited, Pinora now Sono, Peelco and Frutiland Processing Company who all have state-of the art equipment. These companies are mainly operating in the free zones enclave.

| Type of processing company | No of companies | Installed capacity (t/day) | Actual capacity used (t/day) | Underutilized capacity (t/day) |

| Large scale processing companies | 6 | 1,610 | 923 | 687 |

| Small and micro companies | 60 | 330 | 188 | 147 |

| Start-up processing companies | 4 | 176 | 176 | 0 |

| Revamped processing companies | 2 | 104 | 80 | 24 |

| Smoothies Vendors | 100 | 20 | 5 | 15 |

| Defunct processing companies | 44 | - | - | - |

| Total | 216 | 2,240 | 1,372 | 873 |

Source: Hotifresh,2020

Blue Skies Limited: Fresh-cut and juice are the two main product lines. Blue Skies leads the fresh-cut business in Ghana. All fresh-cut mangoes are air-freighted. Most (45%) of its exports are sold through UK retailers and is certified to meet both the general Global GAP standards as well as the individual labels of the different retailers, such as Waitrose or Leaf. The company is also LEAF (Linking Environment and Farming), BSCI (Business, Social Compliance Initiative), Organic, Fair Trade as well as Field to Fork certified. Other market destinations for its fresh-cut exports include the Netherlands, Switzerland, Italy and France.

Integrated Tamale Fruits Company (ITFC) : The company is into fresh-cut and dry mango chips. It is in Gushie, within the Savelugu Nanton District of the Northern Region, with operations across four districts. (Savelugu Nanton, Tolon Kunbungu, Karaga and West Mamprusi). In 2011, the company has exported about 240 tons of fresh mangoes and five 40 footer containers of dried mangoes.

Bomarts Farms Fresh & Dry: Mango Production site is located on 400 acres in the Middle of the Volta Region of Ghana, at Tafi Abuipe near Kpando. Varieties in production are Keith, Kent and Palmer. Supply is from December – February and June - August. The fruit cut pattern is a fillet and slices dried by shelves and preserved with Sulphur dioxide. Bomarts Farms trade its dried mango under the conventional as well as the organic label.

HPW Fresh & Dry Ltd. Produces dried mango, pineapple and whole coconut. The company process over 20,000 tons of fresh fruit, export 2,000 tons of dried fruit annually.

Marketing Agents/Aggregators

A good number of agents/aggregators are available in moving farm produce to direct consumers, processors and to a limited extent, to some fresh fruit exporters.

End Market Actors

Fresh fruit export as well as the local markets, the fresh fruit cut actor as well as actors who cut and dry for export constitute the active drivers of the value chain.

Over a period of five years spanning 2014 to 2018, the number of exporters within the fresh mango value chain increase by152% from 21 to 53. The under-listed actors are the main drivers of the chain as they produce, procure and sell fresh and or value-added mango products.

| Exporter | Volume (Kg) | Earnings ($) |

|---|---|---|

| HPW Fresh & Dry | 805,216 | 34,363,321 |

| Bomarts Farms | 377,434 | 2,552,829 |

| Integrated Tamale Fruits Company | 31,081 | 291,368 |

| VEGPRO | 25,976 | 26,370 |

| Kofi Botchwey | 109,148 | 13,855 |

Source: GEPA Database

Some Exporters of Mango

| Company | Export Destination | Address |

| Blue Sky Product Ghana Limited | United Kingdom The Netherlands France Switzerland Italy | PO Box CT 3506 Phone: +233 244344578 Website: https://www.blueskies.com/ |

| QUIN Organics | European Union | Plot No. M575/2, P. O. Box TF313 Contact person: SAMUEL NII QUARCOO Phone: +233 240 865212, +233 287 010438 Website:http://www.quinorganic.com |

| Eve-Lyn Farms | Middle East Gulf Area | Oyarifa, Off Aburi Rd, Contact person: Bassam Aoun Phone: +233244211370; +233244375131 Website:https://evelynfarms.page.tl/ |

| Samviver Royal Ventures | The company plants/buys farm produce from registered farmers and sell them to exporters. | Naco House. Opposite 41 Nogahill Hotel, Contact person: Ebenezer Inkum Phone: +233 20 837 6618 /+233 57 757 1788 / +233 30 294 8032 Website:http://www.samviverroyal.com |

| Srighan Farms Limited | United Kingdom Sri Lanka | K. Kugathasan Contact person: K. Kugathasan Website:http://www.srighanfarms.com/ |

| HPW Fresh & Dry Ltd | EU |

office-ghana@hpwag.ch |

___

Key Agronomic Practices

Growing Areas

There are two main mango production zones in Ghana, cultivated to an estimated 31,552 acres. The Southern Horticultural Zone (SHZ) which comprises parts of the Lower Eastern, Greater Accra and Volta regions, and the Northern zone which comprises the Ashanti, Brong Ahafo, Northern, Upper East and Upper West regions. In the Central, Upper East and Upper West regions there are a handful of commercial mango farms.

The Brong Ahafo and Northern regions cultivate about 28% and 26% respectively, resulting to 54% of the total cultivated area.

Mango production in the Southern zone and Brong-Ahafo is rain-fed, while some commercial farms in the Northern zone are equipped with drip irrigation.

Growing Seasons

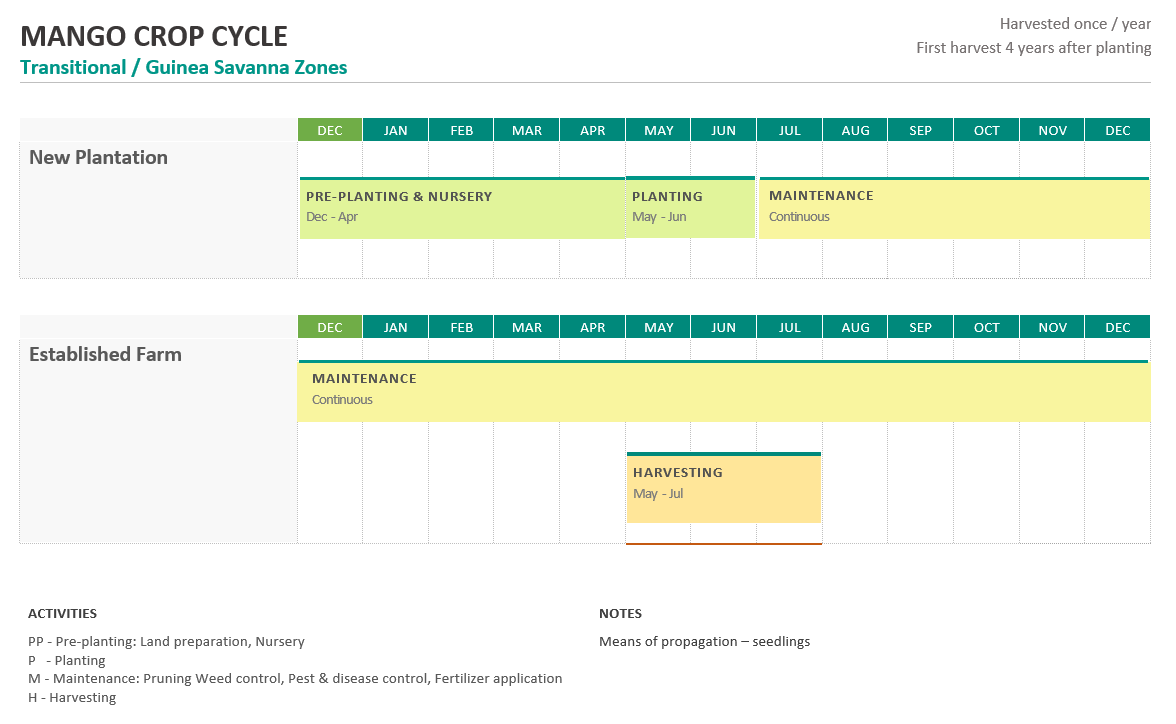

As a multi-year crop, transplanting is done to coincide with the peak of major season rainfall in May/June. The growing zones seasons, harvesting windows and regional distribution is shown below:

Mango growing zones and their seasons

| Mango growing zones | Regions | Harvest season |

Southern (Two Seasons) | Eastern, Greater Accra and Volta | Major season: May-August Minor season: December – February |

Northern (One Season) | Ashanti, Brong Ahafo Northern, Upper East and Upper West |

Mid-April- Mid-August |

Agronomic Practices and their Importance

| Good Agricultural/Husbandry Practice | Brief Description and importance |

|---|---|

| Planting Material | The Northern, as well as the Southern Horticultural zones, have mango germplasm containing the market varieties notably Keitt and Kent to provide reliable true to type scions for mango nurseries |

Nursery Establishment

| Select a good site that is accessible, clean, near a permanent water source, well-drained and free from soil-borne diseases. Seedlings are raised either directly from seed or from seedlings raised as rootstock and budded or grafted with scion or budwood that are desirable. Seedling Production

Grafting Process

|

| Choose suitable soils | Well-drained sandy loams and loams, not waterlogged, pH range of 5.5-7.2 |

Agro Climate Conditions

|

|

| Land Preparation | Clear existing vegetation, stumps, plough and harrow where necessary. Three types of land clearing can be used: Non-mechanised, semi-mechanised and mechanised. |

| Windbreaks and Buildings | Plant Acacia spp and other trees that can reduce high winds and protect the orchard against severe damage from storms. GlobalGAP certification requires a building that houses a toilet, storage area, tools room and packing shed etc. |

Planting

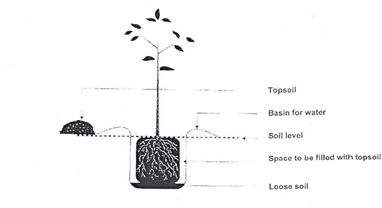

| Transplanting

Transplanting stage: When the seedling is 45 -60 cm tall, it should be transplanted, but 70-80 cm is also all right if it is grown in larger containers Planting

A sketch of planting hole dimensions

A sketch of proper planting of a seedling in a planting hole

Post transplanting Care for young plant

|

| Pruning |

|

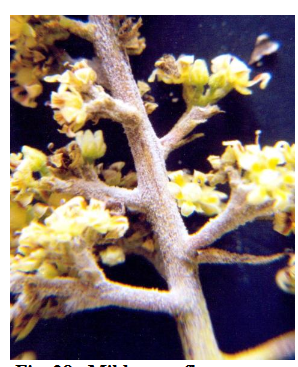

Flowering and Flower Induction | •Two flowering seasons in the south and 1 in the north. •Mango can be artificially induced using

|

Pest and Disease Management

| Scouting for pests and diseases as often as possible ensures that a good management and control program can be implemented. Usually, the earlier a problem is detected the more effective and easier it is to control. In wetter areas, routine spraying may be necessary to manage the incidence of Anthracnose after fruit-set begins. Key Pests and Diseases

|

Soil Fertility Management

| Good plant nutrition is a vital requirement for achieving high fruit yield and quality. Fertilizer application should be timed to coincide the onset of rains and must be location-specific. Apply Nitrogen and potassium after harvest. Use appropriate quantities(kg) and combinations of Nitrogen, Phosphorus and Potassium at the determined plant years. E.g Age 1-3 yrs: 10-15kg of Nitrogen, 5kg of Phosphorus and 10kg of Potassium. Age 6-7yrs: 25-45kg of Nitrogen, 15-20kg of Phosphorus and 25-30kg of Potassium. When trees are above 10 years, apply 40-100kg of Nitrogen, 20-45kg of Phosphorus and 40-120kg of Potassium. For minor nutrients, apply Boron and Zinc as foliar fertilizers. In organic production, apply cow dung. |

| Weed Management |

|

| Mulching | Mulch with dry grass straw |

Harvest Management

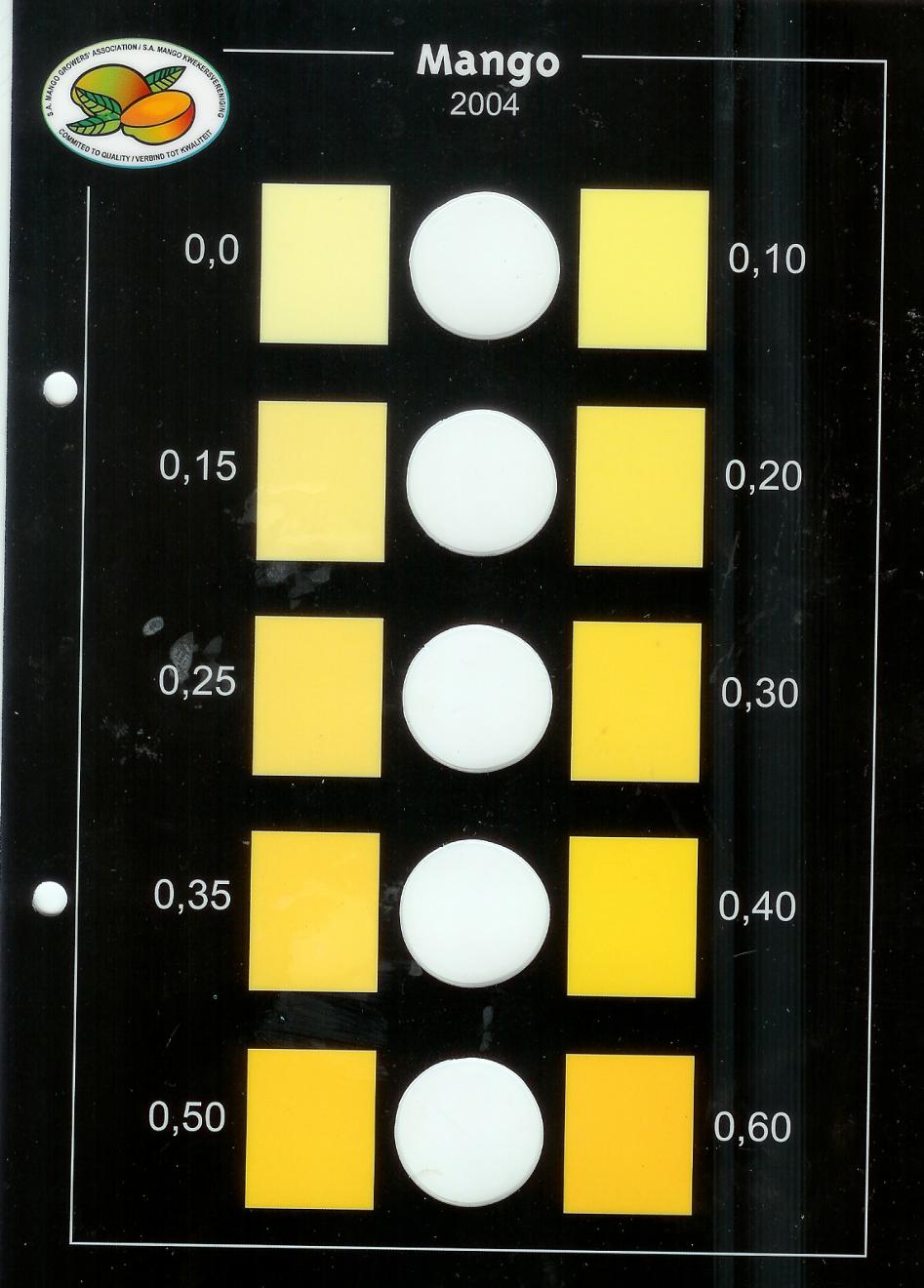

| Start bearing 3 years after planting; Economic bearing start from 7 years and continue to yield for over 30 years. Normally fruits reach the green maturity stage in 100-110 days (4-5 months) from flowering. The amount of yellowing in the pulp indicates maturity of fruit for harvesting. A colour chart developed in South Africa maybe use to determine fruits that are ready for exports. Fruit harvesting and handling should be managed by properly trained personnel to avoid damage. Avoid harvesting immature and over ripped fruits. The average yield of mangoes ranges between 3 – 5 mt/acre even though 10 mt/acre obtainable in a well managed orchards. Fruit Harvesting

Handling Harvested Fruits

Fruits on a rack to prevent ground contact

Field Packing of Fruits

Crate lined with newsprint to prevent bruising Destructive maturity indicators

South African mango colour chart |

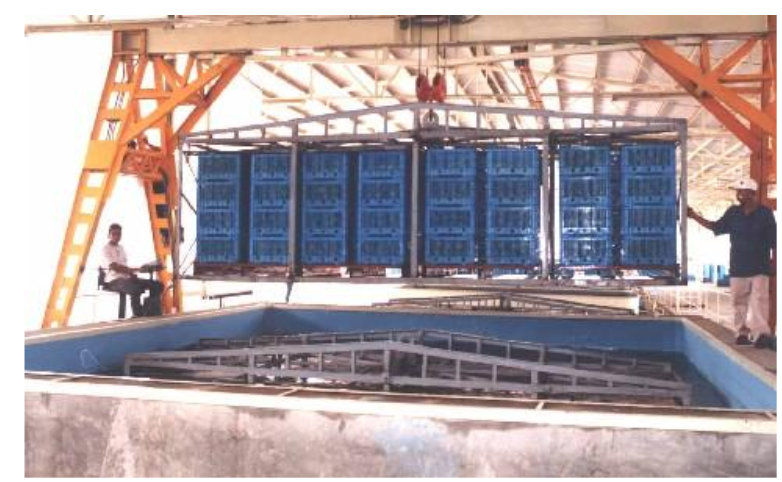

| Post-Harvest Practices | Post-harvest Operations

Packed fruit in a stack ready for the packhouse The operations that are carried out at the packhouse include:

Hot water treatment by immersion  Hot water immersion is the only approved quarantine treatment for mangoes. (US/Japan market demand) |

| Market | Market Requirements

Market Standard Requirements

Food management systems such as:

|

___

Key Risks Along the Mango Value Chain and Mitigation Measures

| Value Chain Actions | Key Risks and Challenges | Mitigation Measures |

Input Supply

| Land Acquisition and Tenure: Land tenure system in Ghana is complex and challenging, making it difficult for investors to access large and contiguous arable land for production. Challenges with land acquisition inhibit farm expansion. | A good background investigation on the land ownership is required. The government must develop a land use policy. |

| Nursery and Planting Material: Lack of quality planting material –Local nursery operators raise seedlings with doubtful progeny and quality. Orchards thus, lack uniformity, fruiting at different periods, and producing fruits of varied qualities. | Strengthening the capacity of operators and farmers can improve yields in the long-term. Ghana needs to work on true-to-type scions and improved budwood. | |

Cost of and access to fertilizer, pesticides and other inputs including irrigation and packaging material, are major constraints for most producers. Rapid local currency depreciation and other factors leading to increased cost of imported fertilizers and pesticides. | Bulk buying and support with subsidized inputs will improve access to inputs. Improved macro-economic environment. | |

| Finance | Access to finance and high-interest rate tend to stifle expansion of production to meet increasing market demand. | Financial institutions should develop agriculture specific products for advancing credit to farmers and other value chain actors. |

Production

| Bacteria Black Spot (BBS) weakens branches and causes premature fruit drop, reducing yields from 6-8 MT to 1-3 MT. Other major diseases are anthracnose and powdery mildew. Most common pests are mealy bugs, stone weevils, fruit flies, scale insects, mites, thrips and borers. | GAPs are required to be supplemented by group monitoring and support. Timely application of pesticides in the right quantities will help reduce the incidence of pest infestation and diseases. |

Weather and Other Climatic Risks: Over-reliance on natural rainfall instead of irrigation. Long spell of dry weather and flooding also affect productivity significantly Water stress at critical times especially during the formative, flowering and fruiting periods can affect fruit productivity and quality. | Harvesting and use of rainwater or wells to irrigate farms especially during the dry season, the formative years and flowering periods. | |

| Post-harvest handling | Post-harvest Management: Improper post-harvest handling reduces the farmers’ margins. | Build a post-harvest training module into extension delivery and use digital videos to reinforce messages. |

Marketing

| Access to fresh fruit market requires farmers to meet Global certification standards. Low quality fruits resulting in insufficient supply. | Individuals and groups should be encouraged and supported to get certified. Train and build the capacity of farmers and other actors to meet the specifications, increase productivity and deliver fruits in a timely manner. |

| Processing | The seasonal nature of mango production. There are supply-side deficiencies with respect to quality, varieties, and seasonality. | Support farmers to implement GAPs to increase productivity and production of quality fruits for processing – fresh-cut, juice and dried mangoes. |

| Consumption | Inadequate local demand for juice and dried mangoes. | Invest in promotion campaigns on the nutritional benefits of mangoes and embark on import substitution drive to increase the consumption of processed mangoes in Ghana. |

| Other | Poor road conditions between production zones, inadequate pack houses and cold chain facilities (storage availability, refrigerated trucks), high freight cost. | Value chain actors should build cold chain facilities. Government should improve roads, and reduce freight cost. |

| Poor fruiting and fruit set | Adopt mango pre-harvest GAPs. Strategically withdraw water to kick start flowering, |

___

Pests & Diseases, Symptoms and Control Measures

Major Pests and Diseases and their Control Measures

| Pests & Diseases | Damages caused | Control measures |

Mealy bug (Drosicha mangiferae).   |

|

|

Fruit flies (Bactrocera)   |

. |

|

Mango Scale Insect (Chloropulvinaria polygonata, Aspidiotusdestructor)   |

|

|

Stone weevil (Sternochetus mangiferae)   |

| Cultural:

Chemical:

|

Mango Thrips: (Coliothrips indicus, Rhipiphorothris cruentatus, and Scirtothrips dorsalis)  |

| Practice strict orchard sanitation. If the infestation is severe, can be controlled by either diametheote (0.1.5%) or Monocrotophos (0.1). |

Powdery mildew (Odium mangiferae)   | Pathogen attacks the inflorescence, leaves, stalk of inflorescence and young fruits with white superficial powdery growth of fungus resulting in its shedding. On Leaves:

On Flowers:

On fruits:

| Prune diseased leaves and malformed panicles harbouring the pathogen to reduce primary inoculum load.

|

Anthracnose (Colletotrichum gloeosporiodes)   | Anthracnose is caused by the fungus Colletotrichum gloeosporioides which attacks leaves, branches, twigs, flowers and fruits. Wet, rainy and humid conditions lead to severity and spread. Symptoms appear as necrotic spots on leaves and later coalesces. Twigs dieback, flowers have tiny spots and fruits abort when infected and mature fruits show damaged pulp.

|

|

Bacterial Black Spot (Colletotrichum gloeosporioides)   |

|

|

Physiological Disorder  | Jelly seed is a physiological disorder in mango fruit. It is characterized by the excessive softening of pulp around the stone in ripe fruits thus lowering the marketability of the affected fruits. The losses due to this problem are estimated to be as high as 30% in some countries. The exact cause of this problem is unknown although it is reported to be brought about by one of the under listed factors:

|

|

___

Market Information on Mango

Marketing of mangoes have traditionally been in the hands of local women sellers over the years. With the increase in production of new, preferred, and exportable exotic mangoes, the marketing of mangoes has assumed a different dimension.

The local internal/domestic marketing channel of fresh fruit mangoes starts at the producer level – independent farms and out-growers sell non-exportable mangoes to processing companies such as Blue Skies, HPW, ITFC and other firms on the basis of contractual obligations and pre-financing arrangements. They sell mangoes that are not sent to processing firms to middle women and retailers who visit the farms during the harvesting seasons to buy mangoes. Some of the producers also sell fresh fruits directly to supermarkets such as Shoprite, MaxMart and Koala.

The European Union and ECOWAS countries offer immediate market opportunities for Ghanaian exporters of fresh mangoes, despite the increasing popularity of mangoes in various parts of the world. This trend has been driven by, the shorter travel hours, historical ties and trade patterns with Europe.

The export of mangoes from Ghana is dominated by a few large farms, producer associations and processors such as Yilo Krobo and Dangbe West Mango Farmers Association, Bomarts, Ghanat, Prudent Farms, Evelyn Farms, ITFC, and HPW.

With 32 market destinations and a global market share of 1.7% , Ghana’s export of Mangoes grew by 28% between 2020 and 2021. The total value of export in 2021 stood at USD 64.6 million compared to USD 50.3 million in 2020. Ghana ranked 11th in the order of countries that exported mangoes to the world in 2021.

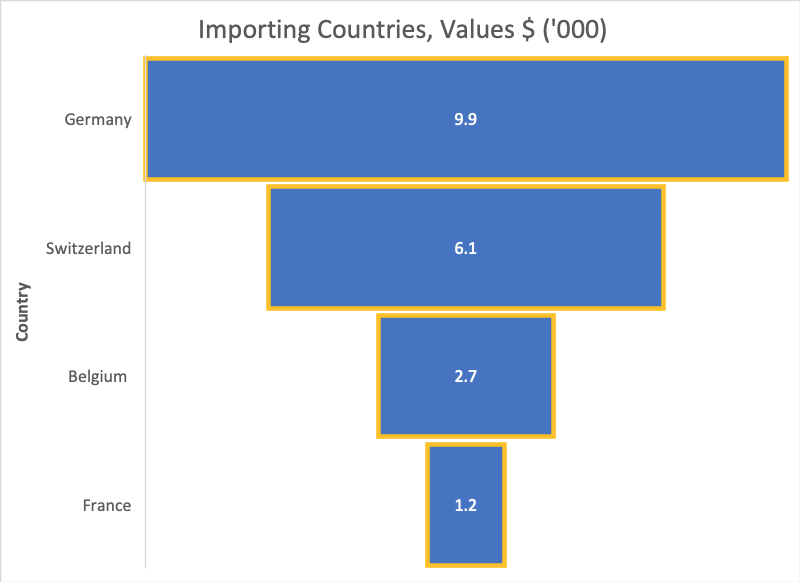

Other prominent importers of mangoes from Ghana were Germany (USD 9.9m), Switzerland (USD 6.1m), Belgium (USD2.7m) and France (USD 1.2m).The major 4 importing countries comprising UK, Germany, Switzerland and Belgium accounted for about 91.4% of total value of export of Mangoes from Ghana. Whilst UK imports of Mangoes from the world grew by 5% between 2017-2021, Ghana’s exports to UK grew by 6% during the same period. Between 2017-2021, exports from Ghana grew by 27% to Germany and 9% to Switzerland.

Export of mangoes from Ghana to EU, increased significantly from 868 MT valued at $2.3 million in 2011 to 4,708 MT valued at $19.5 million in 2021. representing over 1,000%. This has decreased slightly to 1,741 MT valued at $10.85 million in 2017 on account of better prices and exchange rate fluctuations.

Figure 1: Fresh Mango Exports in volumes, MT and value, $, (2011 to 2021)

EU Market Structure

- Market supplied all year round

- August/September and in February supplies are less than during November/December (winter season) and May (with West African supplies).

- Main exporting countries are:

– The UK, Germany, Switzerland and Belgium

Market Trends

- Demand for count 8 and 10 or smaller size 12 per 4kg

- Coloured mangoes (Floridan types) are preferred to green varieties (Amelie types)

- A box of the fruit must not contain fruits weighing less than 4 kg on arrival.

- Pack fruits in excess of the 4 kg probably 4.3 kg as mangoes lose moisture and for that matter weight while in transit.

Main suppliers and seasons

- Brazil: September-February

- Cote d’Ivoire: March – July

- South Africa: December - May

- USA: March to November

- Mexico: May – November

- Venezuela: March – September

- Ghana: May-July and December – February

- Mali – March - June

- Peru: December-April

Price Trends

- Prices of mangoes are differentiated for each channel depending on the quality, size, end-use, distance from marketing centre, who does the harvesting etc.

- On the domestic market, 3 fruits sell for GH¢ 5.0 and GH¢ 10.0 during major and lean seasons respectively

- The average price of large-sized mango for processing is GH¢ 1.8/kg and GH¢ 2/kg during the major and minor seasons respectively.

- Over a period of 5 years (2014 and 2018), the export price of mango per kilogram ranged from $ 4.89 to $ 4.60.

FRESH MANGOES IN THE UK – COMPETITOR ANALYSIS 2018

https://www.gepaghana.org/market-report/fresh-mangoes-in-the-uk-competitor-analysis-2018/

___

Enterprise Budget for Mango

___

Key Policies and Projects

Policies

Sustained Export Promotion Policy

The Ghana Export Promotion Authority (GEPA), established in 1969, and the Ghana Export Trade Information Centre (GETIC), established in 2005, are the main institutions providing trade information and services to the business community, such as market access facilitation for exporting companies, technical advice and human resources development. A National Export Strategy for the Non-Traditional Export Sector (2012-2016) and a National Export Development Programme (2013) also provide guidelines for the implementation of Ghana’s domestic and international trade agenda.

Furthermore, in 2008, Ghana was the second country, after Ivory Coast, to sign a bilateral Economic Partnership Agreement (EPA)-light with the EU, which has eliminated tariffs on virtually all of Ghana’s exports to the EU and on 80 percent of imports from the EU over the next 15 years.

Other policy initiatives include the under listed

- Food and Agriculture Sector Development Policy (FASDEP I&II)

- National Social Protection Strategy (NSPS, 2008)

- Medium-Term Agriculture Sector Investment Plan (METASIP I&II)

- Investing for Food and Jobs (IFJ)

Projects and Interventions in the Horticulture Sub-Sector

- Market Oriented Agricultural Programme (MOAP-GIZ)

- Ghana Agricultural Sector Improvement Programme (GASIP)

- Ghana Agricultural Development and Value Chain Enhancement (ADVANCE II)

- Outgrower and Value Chain Funds (OVCF)

- Horticulture Exports Industry Initiative (HEII)

- Export Marketing and Quality Awareness Project (EMQAP).

___

Mango Growing Seasons and Cropping Cycle

___

Market Preferred Varieties

- KEITT

- KENT

___

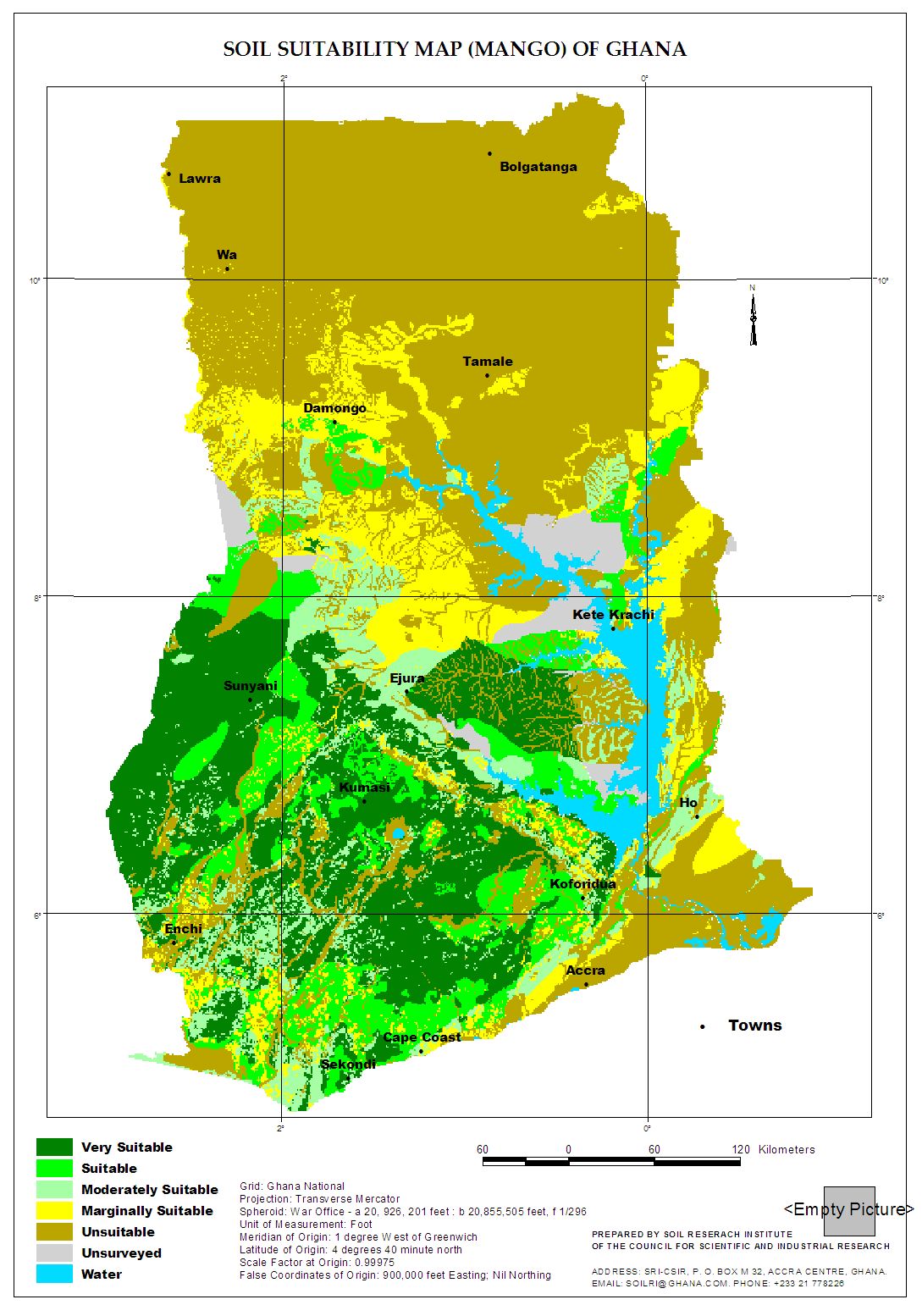

Soil Suitability Map for Mango

___

Agriculture in Africa Media LBG | Email: Ghana@agricinafrica.com

Comments

Post a Comment