Tilapia Summary Fact Sheet

Production

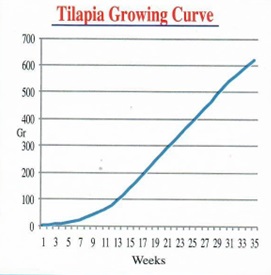

4 – 6 months (Depending on the stocking size, density, management practices and market demand).

- Pond: 691

- Cage: 120 (1,201,262m3)

- 39,353 Mt (2016)

- 43,054 Mt (2017)

- 57,465 Mt (2018)

- 39,263 Mt (2019)

- 64,000 mt (2020)

Organic:

- Poultry Manure

- Pig Manure and

- Cow droppings

Inorganic:

- Single Superphosphate,

- Triple Superphosphate,

- NPK (15:15:15)

Common Organic Fertilizers:

- Poultry dropping,

- Cattle dropping and

- Pig droppings.

Application rate is between 500 -1,000 kg per Ha

- Public - 3

- Private - 105

108 Functional Hatcheries in Ghana

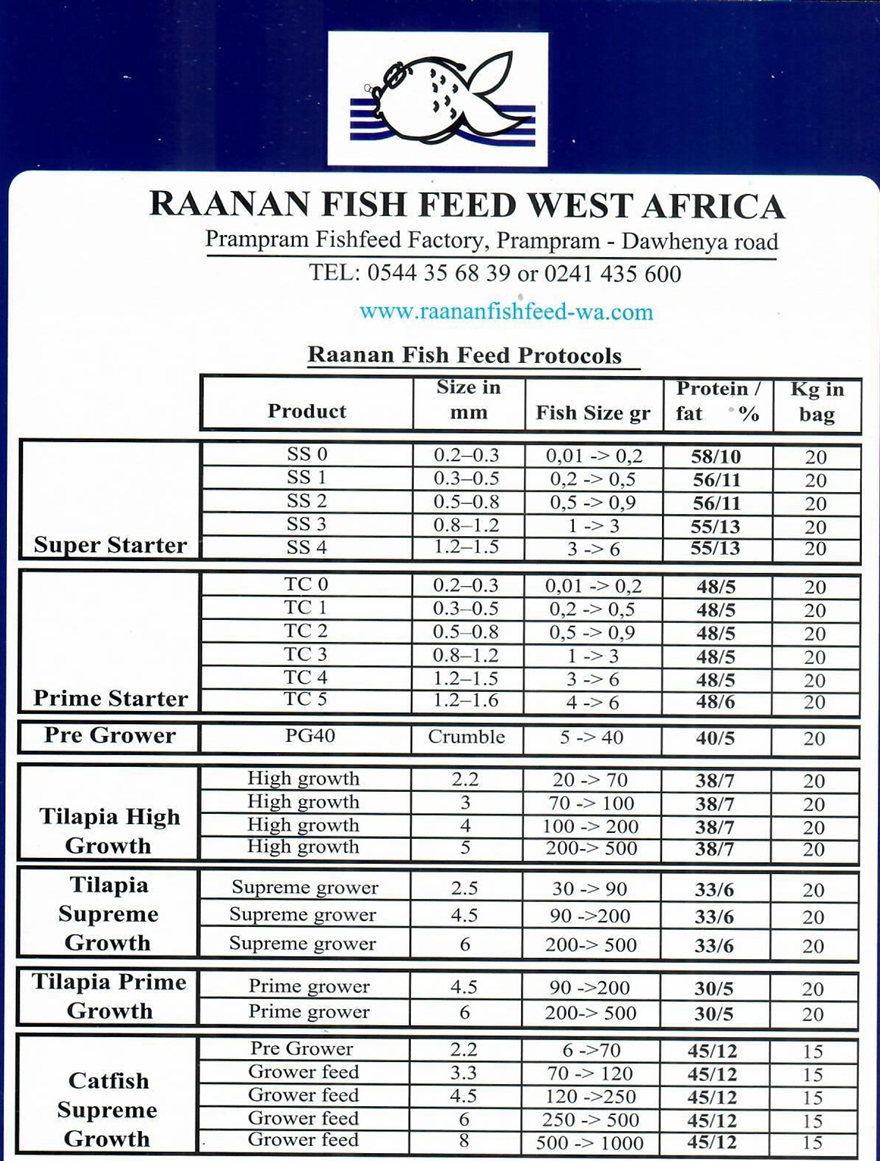

- Raanan Fish Feed,

- Cycle Farms

- Huawei

- Beacon Hill Fish Feed

Four (4) Main Local Producers

Productivity

- Pond: 80,000

- Cage: 350,000

Market & Trade

Ghana's per capita consumption of fish is 25kg far higher than the world's average

___

General Overview of Tilapia Production

Aquaculture is one of the world’s fastest food production sectors with great potential for the supply of protein, income generation, poverty alleviation, enhanced trade and economic benefits. The rapid growth has made the sector important to the economy of many developing countries, including Ghana. Aquaculture can be profitable if the operator has the right natural resources, good management abilities and sufficient capital available for investment in the enterprise. Aquaculture is currently being emphasised in Ghana as an alternative to capture fisheries due to the decline in wild stock from natural water bodies. Ghana is a high fish consuming country, with per capita consumption of about 25kg.

Ghana's aquaculture has produced more than it ever has during the past ten years, which has boosted livelihoods and earnings (Ragasa et al. 2018). According to research, the development and release of an improved local Akosombo strain in 2005, government policy support initiatives, better management techniques and technologies at hatcheries and grow-out production systems, and the accessibility of locally produced high-quality feeds are the main causes of Ghana's recent growth in tilapia farming (Ragasa et al. 2018). In order to expedite the development of aquaculture, the government has expanded its flagship initiative, Planting for Food and Jobs (PFJ), to include Aquaculture for Food and Jobs (AFJ).

A total of 440,000 tons of fish are produced annually in Ghana through marine, freshwater, and aquaculture fisheries. Up to 2.2 million people rely on the fishing industry for their livelihood. However, the majority of Ghana's fish resources are severely overfished, and the nation can only provide 50% of its yearly needs from all sources.

Tilapia culture in Ghana takes place in ponds, usually in polyculture with other species like the African catfish, Clarias gariepinus and the African bony tongue Heterotis niloticus and in cages mainly on the Volta Lake.

Small-scale tilapia farmers practice both extensive and semi-intensive systems, focusing on the “Akosombo” strain of the Nile tilapia (Oreochromis niloticus) in monoculture or polyculture. This strain is given priority due to its better characteristics, which include fast growth, short food chain, efficient conversion of food, high fecundity, tolerance to a wide range of environmental conditions and good product quality. Their ability to over-reproduce in ponds requires the use of male monosex (all-male) populations.

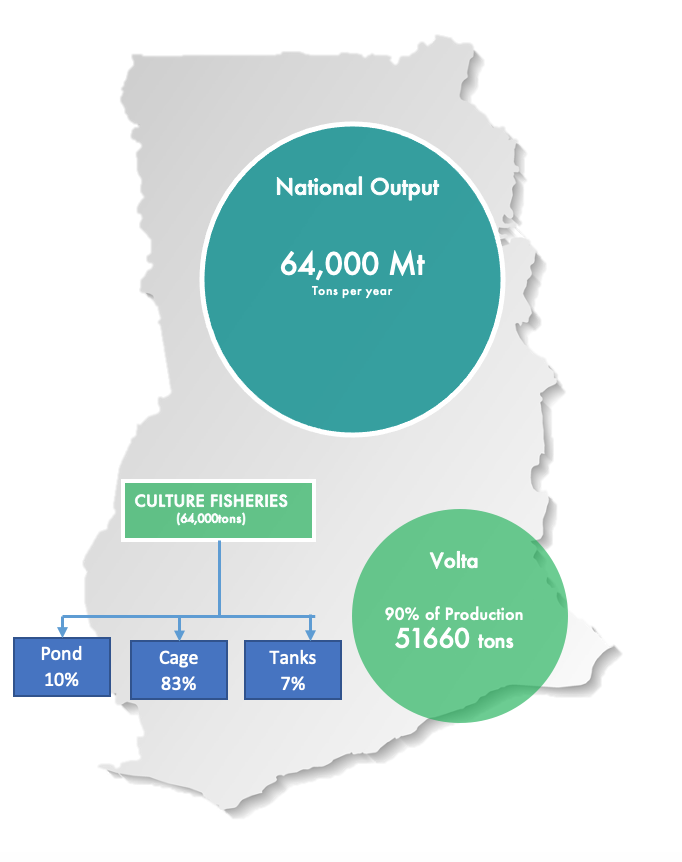

Figure 1: Map of Ghana showing aquaculture production

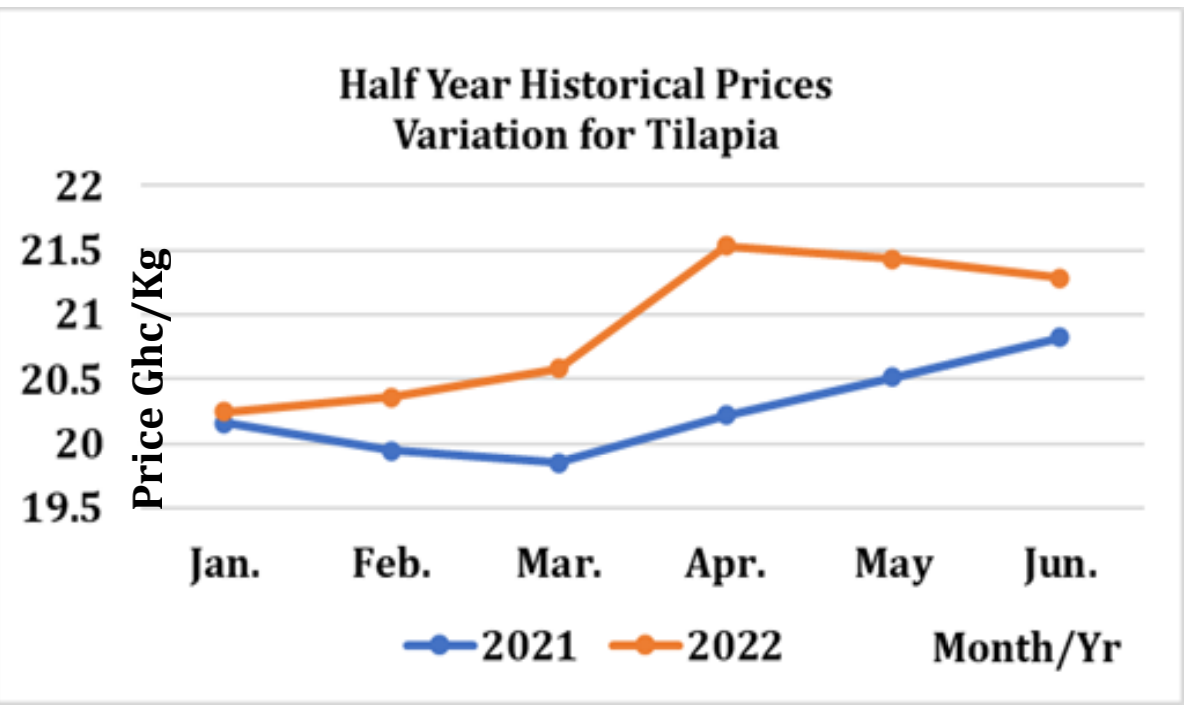

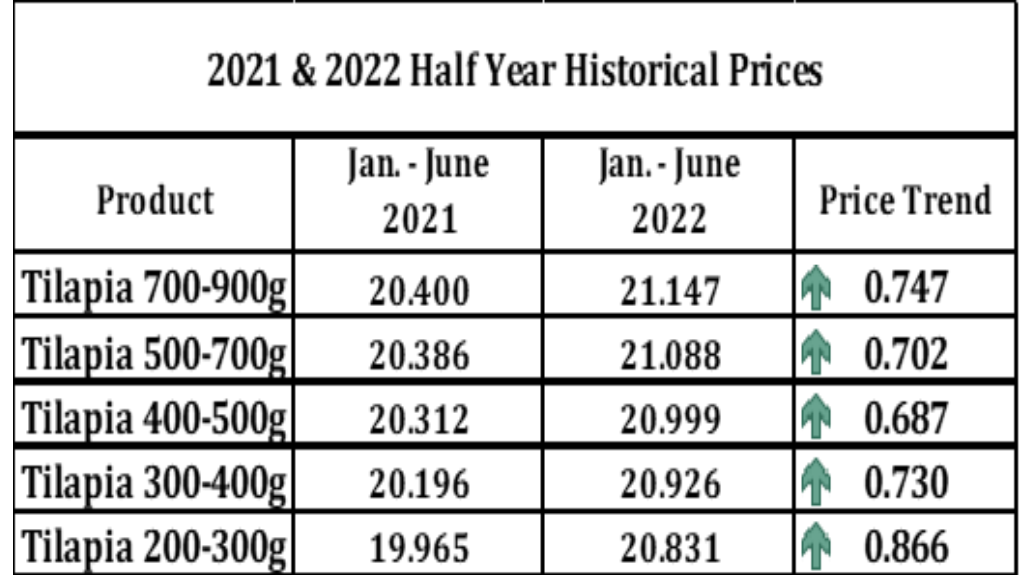

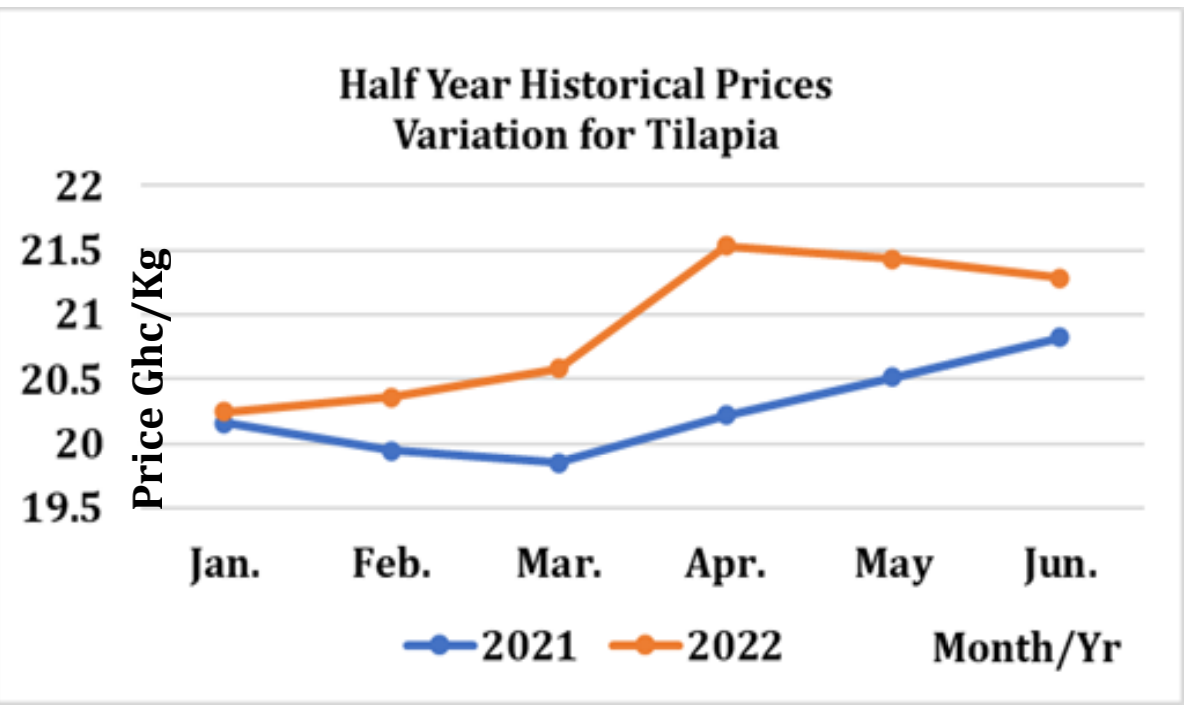

The first half of 2022 saw a sharp increase in the cost of tilapia and catfish, particularly around Easter. The increase is linked to a rise in the price of fish feed components including maize, soy, and fish oil on the international market. The price increase of tilapia and catfish in Ghana during the first half of 2022 can also be attributed to an increase in import levies, a depreciation in the local currency against key foreign currencies, and a high cost of energy.

Figure 1: Half Year Prices Variation for Tilapia

Currently, there is a ban on the importation of tilapia in all forms (dead and live) into the country, except for research, upon permit from the Fisheries Commission.

Tilapia grows rapidly on formulated feeds with lower protein levels and tolerate higher carbohydrate levels than many farmed species. They can also accept feeds with a higher percentage of plant proteins. It is easy to breed tilapia and culture them intensively and economically. They are relatively resistant to poor water quality and disease. Their ability to over-reproduce in ponds requires the use of male monosex populations. Their hardiness and adaptability to a wide range of culture systems has led to the commercialization of tilapia production in more than 100 countries. Their widespread consumer appeal will, thus, fuel the expansion of the tilapia industry for years to come.

Table 1: S.W.O.T Analysis

Strengths

| Weaknesses

|

Opportunities

| Threats

|

General Overview of Aquaculture Production in Ghana (2015 – 2019)

| Indicator | Year | ||||

| 2015 | 2016 | 2017 | 2018 | 2019 | |

| Production Facilities | |||||

| No. of Ponds | 3,915 | 4,132 | 4,385 | 4,523 | 4,925 |

| No. of Cages | 7,607 | 8,415 | 8,415 | 10,102 | 10,102 |

| Total | 11,517 | 12,547 | 12,800 | 14,625 | 15,027 |

| Total Surface Area of Ponds (ha2) | 805.00 | 833.40 | 846.21 | 857.73 | 934.00 |

| Total Volume of Cages (m3) | 1,699,328 | 1,080,702 | 1,080,702 | 1,201,262 | 1,201,262 |

| Fish Production, mt | |||||

| Ponds | 2,410.00 | 2,713.70 | 7,407.24 | 11,069.00 | 11,919 |

| Cages | 42,150.00 | 47,171.70 | 43,500.00 | 56,645.00 | 30,345,00 |

| Dams & dugouts | 2.050 | 2,584.60 | 6,500 | 8,906 | 10,086 |

| Total (mt) | 46,610.00 | 52,470.00 | 57,407.24 | 76,620.00 | 52,350.00 |

| % Contribution | |||||

| Tilapia (%) | 92 | 93 | 80 | 91 | 74 |

| Catfish (%) | 8 | 7 | 20 | 9 | 26 |

| No. of Operators | |||||

| Small-scale farmers (<51mt/annum) | 2,167 | 2,160 | 1,852 | ||

| Medium scale farmers (51-100mt/annum) | 15 | 14 | 14 | ||

| Large scale farmers (>100mt/annum) | 11 | 11 | 11 | ||

| Total | 2,193 | 2,185 | 1,877 | ||

| Average weight of fish (g) | Feed (% body weight) |

| 10 - 15 | 20 |

| 15 - 30 | 15 |

| 30 - 50 | 10 |

| 50 - 100 | 5 |

| 100 - 200 | 4 |

| Above 200 | 3 |

___

Aquaculture Value Chain

Input Dealers

The input suppliers consist of brood stock developers (who also sell fingerlings), fingerling producers (hatcheries), feed producers/suppliers, pond and cage constructors, and fishing net suppliers. Input suppliers market their products and services mostly through delivery and/or wholesale and retail outlets. Apart from the fishing net suppliers whose primary target market are fishermen, fish farmers are the primary target markets for all the input suppliers. With the exception of the brood stock developers and hatcheries, which are a mixture of government and private businesses, all other input suppliers are private individuals and organizations.

Majority of the feed producers and suppliers are relatively younger in the aquaculture business compared to the other input suppliers. Over 85 % of the feed suppliers started their business between the years 2010 and 2012. The input suppliers are optimally located in four regions: Ashanti, Brong-Ahafo, Eastern, and Greater Accra regions, close to where major aquaculture operations are situated.

The pond and cage construction business is composed of individual businesses as well as group or cooperate businesses. The pond constructors have been in the business longer than cage constructors, which is expected considering that cage aquaculture is relatively new in Ghana compared to earthen pond aquaculture. For a 300 m2 pond, it takes a single individual about 1 month to complete a manual construction. Mechanical excavators can reportedly do the same job for a relatively shorter time. For cages, it takes about 3 weeks for an individual to construct a 25 m2 fish cage. Both pond and cage constructors were located close to the respective ‘hot’ spots of aquaculture.

Wontesty Ventures one pond construction company specialises in the planning, design, construction and maintenance of aquaculture production and holding facilities, with a focus on Recirculating Aquaculture System (RAS) and lined ponds.

Commercial fishing net supply to fish farmers is still a burgeoning business depending heavily on the development of cage aquaculture, since most earthen pond farmers use few fishing nets. Fishing net suppliers’ retail imported products such as nets, ropes, and twines mostly from Korea and Vietnam. Only one feed supplier produces fish feed locally. All other suppliers import fish feed mainly from Brazil, the Netherlands, and the USA. The fish feed suppliers provide feed suitable for use by brood stock developers, hatcheries, and fish producers.

Both the brood stock developers and the hatcheries provide aquaculture training and general technical advice to farmers and the public. Depending on the nature of training and duration, these services could be free or attract fees. Some large-scale fish producers develop brood stock and produce fingerlings, but only for their own use.

Majority of the hatcheries produce and supply sex-reversed tilapia fingerlings of about 5g to farmers. However, the supply of 2g of fingerlings, especially to cage fish producers, is common since demand is high and it takes about 7 – 8 weeks to obtain 5g of sex-reversed fingerlings. Typically, farmers have to place orders for fingerlings, and depending on the size of orders, it may take weeks to have their orders fulfilled. Since one major brood stock developer is responsible for producing and supplying the improved ‘Akosombo’ strain of the Nile tilapia to hatcheries across the country, it can be assumed that the ‘Akosombo’ strain of the Nile tilapia is the major strain cultured in Ghana.

There are currently 108 functional hatcheries in Ghana - three public and 105 private, with an additional three public hatcheries under construction. There are four local feed producers with numerous dealers.

Government hatcheries produce certified improved seed for hatcheries. There are three publicly accessible hatcheries: the Ashaiman Aquaculture Demonstration Center in Greater Accra; the Pilot Aquaculture Center in Kumasi, Ashanti Region; and the Water Research Institute hatchery in Akosombo, Eastern Region.

Imported Feed:

Seven different types of imported feed are available from a few major players. The reliance on imports and the presence of import duties & charges puts them at a 30% cost disadvantage to local producers. etc.

- 70% of total feed production due to a cost advantage

- Top Seller is Pelletised fish feed (6mm, 33% protein), Lower cost versus imports & so is most popular.

- Exports to the region (+-5000 tons)

- Key Suppliers- Raanan fish feed, Aller aqua, Koudijs, Skretting, Nicoluzzi, Coppens, Cargill AquaFeed, Beacon, Pira and Cycle farms, a recent start up, produces insect meal locally.

- Akriset Enterprise: Sells fish farm input and products ranging from equipment for fish farm setups, fish hatchery operations, grow out production and other accessories except fish feed such as Ovaprim, Artemia, Aerators, oxygen ring blower, water quality meters/probes, harvesting nets etc.

- CCT Group Limited: Imports and distribute fishing gears

- Virbac Aquaculture Division: Produces Tilavac S3 vaccine for protection against Streptococcus agalactiae seroytpe Ia,Ib, and III in NIle Tilapia.

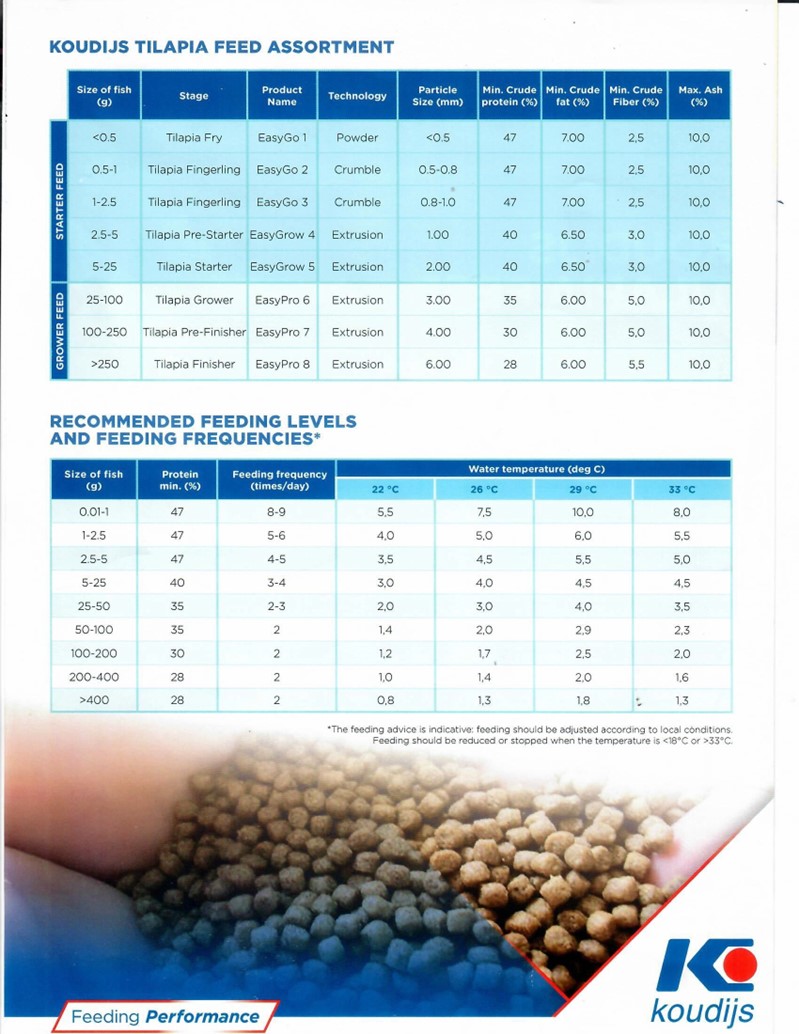

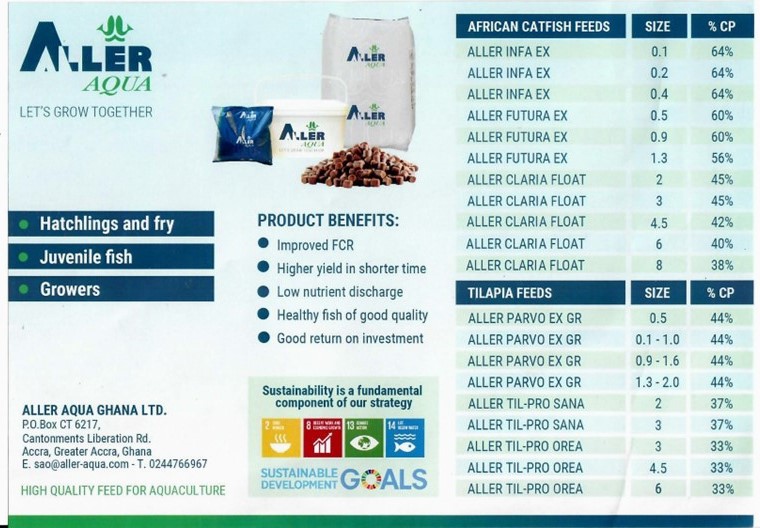

Fish Feed Formulations by Some Companies

Producers

Two primary categories of producers exist: pond and cage grow-out farmers. However, a few cage farmers also operate ponds. Cage farmers produce only tilapia, whereas some pond farmers culture additional species such as Clarias sp., Heterotis niloticus, and Parachanna obscura in a polyculture system. Cage farmers are characterized by intensive production and may be grouped into small-scale (<10 cages), medium-scale (10 – 50 cages), and large - scale (>50 cages) operations.

Pond and cage grow-out farmers focus on producing table-size tilapia for sale to traders, food service providers, and final consumers. Some grow-out tilapia producers also double as hatcheries, marketing fingerlings to fellow grow-out farmers. It usually takes cage farmers about 6 months to grow fish to obtain 2–3 pieces of fish per kg. However, pond farmers may obtain 4–5 pieces per kg for the same period of time. The difference in productivity can be attributed to a number of factors.

Cage farmers grow sex-reversed fingerlings, and though 100% all male fingerlings are presently not attained in Ghana, similar to what is reported elsewhere in Africa, the cage environment does not support prolific breeding of tilapia. Conversely, pond farmers use both mixed and sex-reversed tilapia and have problems such as overpopulation and reduced growth in their ponds. Whereas cage farmers use high-quality commercial fish feed, only a limited number of pond farmers consistently use commercial feed because of capital constraints. Cage farmers have relatively shorter and specialized marketing channels compared to pond farmers.

Ninety-five percentage of the cage farmers sold their fish exclusively at the farm gate and mostly to retailers, whereas many pond farmers have varying customer types (neighbors, retailers, and distributors), and only about 31 % sold exclusively at the farm gate. Thus, cage farmers may have a high efficiency than pond farmers because of the reduced transaction cost in their marketing.

The major constraints to production include high cost of inputs (especially feed), inadequate or lack of credit facility, inadequate technical know-how (especially with small-scale farmers).

Major producers of tilapia include:

- Tropo Farm Limited sells under the name Volta Catch Tilapia is the premier aquaculture company in Ghana. Farm located in Mpakadan, Asuogyaman District with annual production capacity of more than 12,000 MT/yr in 2022.

Processors,

Farmed tilapia is mostly marketed fresh compared to wild tilapia, which may be smoked, dried, or salted. Thus, processors of farmed fish, who are predominantly women, are engaged mainly in gutting and scaling of the fish. The processors are central to the value chain because, apart from the input suppliers, they interact with all key actors in the value chain. Even though they do not purchase the fish themselves, they provide ready services to traders, food service providers, and consumers at the point of sale. Gutting is usually done on the farm for a fee. Scaling may be done together with gutting if the buyers are food service providers or consumers. Otherwise, the service is usually offered at distribution points or sales outlets.

These processors may be local residents around farms and sales outlets or may commute to such places to offer their services. They are mostly individuals accountable to themselves, but may work in a group. A group of 10 female processors is not uncommon, and one can observe up to 4 of such groups at Galilea market, a busy tilapia (both wild and farmed) sales outlet close to Kasoa in the Central Region. Even though processors’ major strength in the value chain is the ability to operate a niche market, their current processing activities show a significant lack of adequate food safety knowledge. This poses a threat to their business, particularly as the aquaculture industry grows and food safety regulations become mandatory.

Traders Marketing of farmed tilapia occurs through three key traders: wholesalers (who may also retail), distributors, and retailers. Wholesalers buy large quantities of fish. Some tilapia producers also wholesale their fish at sales points.

Wholesalers sell at designated locations in owned or rented stores. Typical wholesalers supply fish to both distributors and retailers and are usually the traders who deal directly with the farmers.

Distributors typically sell smaller quantities of tilapia compared to wholesalers and usually deliver to retailers, sell at cold stores, or deliver to restaurants. Retailers trade in small quantities of tilapia and usually sell in the community markets directly to consumers.

Retailers sell in stalls (owned or rented), on table tops or in pans. Some retailers also hawk their wares as a means of increasing sales. The main value addition performed by all the traders is packaging and facilitation of product movement from supply centers to demand centers. However, retailers also scale fish free of charge to customers as a sales-increasing strategy. Customers may also obtain limited free ice from wholesalers, distributors, or retailers to preserve their fish.

DAA Fisheries Training Center (DFTC) located at Kokrobite accredited by COTVET provides training in fish processing.

Traders

Cultured tilapia is mainly sold fresh at the farm gates and designated markets. Fish traders include wholesalers (private individuals and producers) and retailers. Some producers wholesale their fish at farm gates or designated points to retailers. Typically, retailers buy directly from small-scale producers at farm gates or from wholesalers and sell by hawking or at designated points, offering other services such as descaling (removal of scales) and degutting (removal of entrails) of the fish to the final consumer.

Food services include restaurant operators, tilapia joints, supermarkets and food vendors. Except for supermarkets which sell fresh fish only, all foodservice providers offer value-added services such as smoking, grilling and frying.

Food service providers represent another group of traders. They include restaurants, tilapia ‘joint’ operators, ‘chop bar’ operators and supermarket. Restaurants are either standalone entities or within hotels. Most restaurants perform a variety of value addition activities including cleaning, dressing, and seasoning. All the restaurants surveyed had grilled tilapia and ‘banku,’ a new Ghanaian delicacy, on their menus. The restaurants are noted for requiring large-size tilapia (400g and above) because of their customer base. Consequently, cage farmers tend to be advantaged when they target restaurants compared to pond farmers.

The tilapia ‘joint’ operators are individuals or groups that specialize in grilling tilapia and like the restaurants, serve it with ‘banku.’ Tilapia ‘joints’ may be found at roadsides of busy towns and operate typically between 16:00 and 23:00 hours. Tilapia ‘joints’ are increasingly being situated near pubs and drinking bars to take advantage of the customers that frequent there. Compared to restaurants and tilapia ‘joints,’ ‘chop bars’ are affordable eating places where one can purchase cheap tilapia. Most ‘chop bars’ are noted for their wide range of local Ghanaian dishes. Thus, ‘chop bar’ operators tend to boil or steam tilapia in contrast to grilled tilapia.

Some Tilapia outlets

- Volta Catch Tilapia: The company retail and wholesale sales depots in Malam Atta, Kasoa, Tema, Atimpoku, Takoradi and Kumasi.

Consumers

Tilapia is consumed in various forms, including smoked, salted and dried (koobi) grilled, fried, and cooked. Final consumers obtain fish along the distribution chain - producers, wholesalers, processors, retailers and foodservice providers.

Even though consumers neither participate in the production nor value addition, they are part of the chain because they are the driving power of the whole process. Therefore, consumer demand is a determining factor for the kind, amount and quality of a product (UNIDO, 2009).

___

Key Production Practices for Tilapia

Key Production Practices and their Importance

- Commercial tilapia production generally requires the use of male monosex populations. Male tilapia grow approximately twice as fast as females. Therefore, mixed-sex populations develop a large size disparity among harvested fish, which affects marketability. Moreover, the presence of female tilapia leads to uncontrolled reproduction, excessive recruitment of fingerlings, competition for food, and stunting of the original stock, which may not reach marketable size.

- In mixed-sexed populations, the weight of recruits may constitute up to 70 percent of the total harvest weight. It is therefore necessary to reverse the sex of female fry. This is possible because tilapia do become sexually differentiated for several days after yolk sac absorption. If female tilapia receive a male sex hormone (17 α methyltestosterone, MT) in their feed, they will develop as phenotypic males. Fry collected from breeding facilities need to be graded through 3.2 mm mesh material to remove fish that are >14 mm, which are too old for successful sex reversal.

- Swim-up fry are generally <9 mm. MT is added to a powdered commercial feed or powdered fish meal, containing >40 percent protein, by dissolving it in 95-100 percent ethanol, which is mixed with the feed to create a concentration of 60 mg MT/kg feed after the alcohol has evaporated. The alcohol carrier is usually added at 200 ml/kg feed and mixed thoroughly until all the feed is moist. The moist feed is air dried out of direct sunlight, or stirred in a mixer until dried, and then stored under dark, dry conditions. Androgens break down when exposed to sunlight or high temperatures.

- Fry are stocked at 3 000 to 4 000/m2 in hapas or tanks with water exchange. Stocking densities as high as 20 000/m2 have been used if good water quality can be maintained. An initial feeding rate of 20-30 percent body weight per day is gradually decreased to 10-20 percent by the end of a 3 to 4 week sex-reversal period. Rations are adjusted daily, and feed is administered four or more times per day. If sex-reversal is conducted in hapas, the feed must be of a consistency that allows it to float. Otherwise a considerable amount of feed would be lost as it settles through the bottom of the hapa. Sex-reversed fry reach an average of 0.2 g after 3 weeks and 0.4 g after 4 weeks. The average efficacy of sex-reversal ranges from 95 to 100 percent depending on the intensity of management.

| Good Aquaculture Practices (GAgPs) | Brief Description and Importance |

Fish Seed

| All-male tilapia (Oreochromis niloticus) of 5 – 10g. Selection of species or strain is governed by legal provisions. Only Akosombo strain of tilapia is allowed for cage farming in the Volta lake.

|

| Brood Stock/Fingerling Production | |

| Fingerlings | Fingerlings may be sourced from certified hatchery operators or produced on-farm. Production on-farm is more reliable but more demanding. |

Site Selection

| Select site of soils with clay content of 30-35% for pond construction to ensure impermeable pond bottom and dikes (to minimise water losses). Topsoil should be used to dress the pond dikes. Other factors to consider:

Environment - do not locate your farm in a wetland or flood plain of a river |

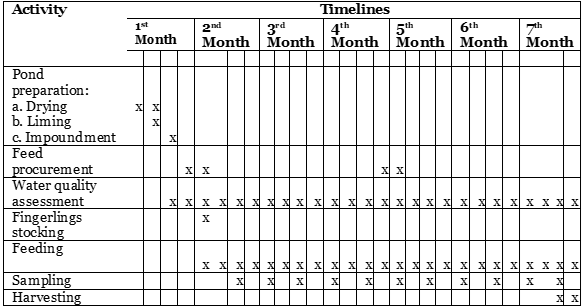

| Production Calendar for Tilapia |  |

| Pond Preparation | Pond preparation involves complete drainage of pond, removal of weeds, complete drying of pond bottom, removal of excess silt, disinfection, filling of pond with water. Some considerations in pond preparation:

For cages:

|

Production system design

|

Recirculation systems have been developed to culture fish all year-round under controlled conditions. Although the design elements of recirculation systems vary widely, the main components of RAS consist of fish rearing tanks, a solids removal device, a biofilter, an aerator or oxygen generator and a degassing unit. Some systems apply additional treatment processes such as ozonation, denitrification and foam fractionation. Rearing tanks are generally circular to facilitate removal of solid materials, although octagonal tanks and square tanks with rounded corners provide a suitable alternative with better space utilization. |

Stocking

|

|

| Feeding | Fish feed can be in many forms and sizes such as powder, pellets, or crumbles depending on the age of the fish, the feeding habit and the culture. Floating pellet feeds are suitable for fish that feed from the surface of the water, example tilapia. Sinking pellet feeds are good for fish that feed from the bottom, example catfish. Types of fish feed and their examples:

Feed Conversion Rate (FCR)

Importance of FCR

Thus, the FCR allows the farmer to make wise choices in selecting and using feed to maximise profitability. Some factors that affect FCR

|

Water Quality

| Good quality water is the foundation of fish health and successful tilapia culture. Water quality parameters to be monitored include dissolved oxygen, temperature, ammonia, alkalinity, pH, turbidity, total hardness and nitrite. The geographic range for tilapia culture is limited by their temperature-sensitivity. The ideal water temperature for optimal growth is 25 – 30 ºC. Other water quality parameters and their acceptable ranges include:

Fish production can be greatly affected by excessively low or high pH. Extreme pH values can even kill your fish. The growth of natural food organisms may also be greatly reduced. The critical pH values vary according to the fish species, the size of individual fish and other environmental conditions. Pond water with unfavorable pH can be corrected:

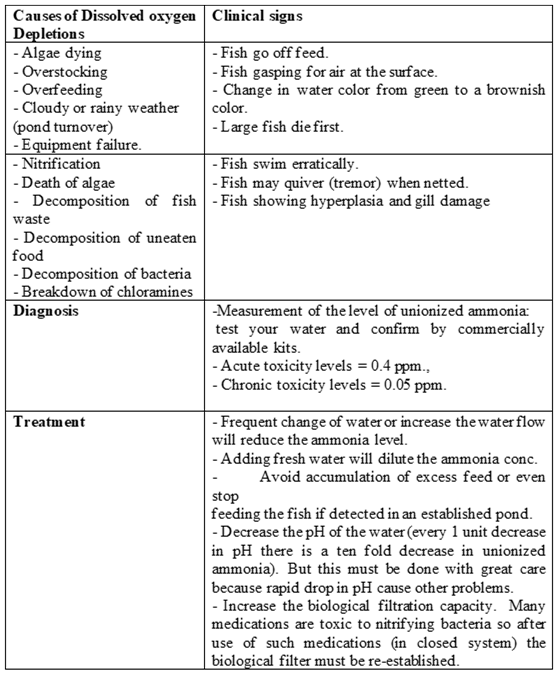

Signs of Pond Water Oxygen Depletion- Water chemistry (ammonia, nitrite, extreme pH) - Gill or skin parasites - Bacterial gill disease (poor water quality, wrong sized food) - Anaemia - Toxins (insecticides, pesticides, fish medications like formalin, hydrogen sulfide)  |

Pond Management | Fishpond bottom soil fertility management include:

Population ManagementBiological constraint to tilapia culture is early sexual maturity. This results in spawning before attaining market size, overpopulating the pond, hence the need for pruning. Husbandry practices have evolved to prevent overcrowding and the need for pruning:

Disinfection – to eliminate aquatic animal pathogens and their vectors Use of probiotics – to enhance beneficial chemical and biological processes and improve soil fertility. Reduced feed intake Reduced feed intake or reluctance to eat is usually associated with stress, but disease should be considered as well e.g. in Enteric septicemia of catfish (ESC) may be the first clinical signs.  |

Pest and Disease Management

| Aquaculture pests include birds, reptiles, wild fish and insects. Effective pest management is reliant on knowing the pest and the mode of entry into the pond. Control measures include: Birds: placing decoy / netting material over the entire pond. Reptiles/wild fish: cover the inlet and outlet pipes with nets; clear weeds and keep grass on the dikes very low; maintain proper fencing and protection around the farm/pond; remove any dead fish from the pond as soon as spotted; Several diseases of tilapia are known to be caused or exacerbated by inadequate management/husbandry practices such as poor water quality, inappropriate water quality, inappropriate nutrition, aquatic environment degradation. |

| Pond Fertilization | Fertilization – to supply nitrogen in order to increase soil organic matter degradation. Addition of inorganic and/or organic compounds.

|

Weed Management

| Aquatic plants that cause weed problems in aquaculture are algae (the most common), floating weeds, emersed weeds (weeds above water) and submerged. The most effective way to avoid invasion by aquatic weeds is through exclusion or preventing them from entering into the pond – careful pond site selection and proper pond construction. Excessive algae may be due to high feeding rates required to produce high fish yields or pond pollution. Once in the pond, the following practices may be adopted:

|

| Biosecurity | Disease outbreak remain a major threat in tilapia culture. A biosecurity plan is needed to prevent the introduction and/or spread of disease agents.

|

Harvest and Post-Harvest practices

| Before harvesting

Harvesting

After harvest

|

___

Key Risks Along the Tilapia Value Chain and Mitigation Measures

| Value Chain Actions | Key Risks and Challenges | Mitigation Measures |

Input Supply

| Social risks (competition for key resources from other sectors) The high cost of feed Low quality of feeds | Facilitate the development of raw material base for feed preparation; Develop species-specific feed; Strengthen production and marketing associations to facilitate the supply of input (facilitate trade relationships) |

| Low quality of fingerlings | Procure fingerlings from certified hatcheries | |

| Hatcheries concentrated in Greater Accra and Eastern regions leading to high cost of transport and mortality of quality fingerlings especially for small scale farms | Increase number of hatcheries across the regions Provide suitable transportation system for movement of fingerlings Subsidize cost of fingerlings | |

| Exchange rate volatility affects the cost of inputs especially soya bean and vaccines | Consider using substitutes for imported ingredients like soya meal | |

| Finance | Inadequate financing | Re-allocate resources and scale production operations appropriately |

| Production | Pathogen risks | Adopt good aquaculture practices - Develop protocols to control and prevent diseases |

| Ecological / pests / predator risks | Adopt good aquaculture practices - Develop protocols to control and prevent pests (biosecurity measures) |

| Environmental risks (Severe weather pattern, pollution from agriculture chemicals and oil spill) | Ensure proper site selection; conduct Environmental Impact Assessment (EIA) and regular water monitoring | |

| Operational risks (poor planning, workplace injuries) | Build capacity; ensure safety protocols | |

| Equipment failure | Ensure regular inspection and maintenance of equipment | |

| Lack or loss of skilled labour | Employ additional labour; | |

| Genetic risks | Switch source of fingerlings; select suitable sites away from wild tilapia populations; screen inlet and outlet pipes to prevent the entry of wild fish into the pond; | |

| Social risks (theft/vandalism) | Prevent unauthorised human access to the site / employ physical security; | |

| Presence of wild and female tilapia in the pond/cage affects health and productivity | Sanitise to remove any trace of foreign tilapia and female strains | |

| High levels of antibiotics and vaccines | Strengthen regulation and monitoring Intensify education and awareness Ensure responsible use of vaccines and antibiotics | |

| Post-harvest handling | Food safety and public health risks | Adopt food safety and hygienic practices |

Marketing

| Decreasing prices of outputs | Diversify product mix |

| Increasing production costs | Change business strategy/production technology | |

| Processing | Food safety and public health risks | Adopt good sanitary practices / improved post-harvest technologies and product development |

| Consumption | Social risks (food safety) | Strengthen farmers and women groups in fish handling; |

Emerging Risks

Climate Change

Aquatic systems that sustain aquaculture are undergoing significant changes as a result of global warming and projections indicate that these changes will be accentuated in the future. Effects of climate change on aquaculture are reflected by temperature changes in both water and air. Extreme weather conditions are important effects, either as storms causing material damage or flooding of farms. Fish are subject to different stresses and physiological effects, affecting growth and development, which may further increase their susceptibility to diseases and infections. There are also concerns about new and emerging diseases and parasitic infections. A core challenge, however, is our inability to understand and anticipate the effects of gradual change as opposed to extreme events.

Pandemics (e.g. COVID - 19)

COVID - 19 induced uncertainties, fear and panic which negatively impacted fish production decisions, leading to among others, reduced investment in aquaculture, high inflation in fish and fishery products and loss of some livelihood opportunities. Aquaculture supply chains are severely impacted by the closure of food service sectors – schools, restaurants, etc. This reduced fish demand and consequently prices, resulting in loss of investment. There are still uncertainties ahead, particularly with regards to the duration, severity of the pandemic and consequently, fish production decisions.

Introduction of lockdown led to low production due to:

- Limited access to inputs and other services

- Limited number of staff (as a result of flexible working hours) to implement activities

- Delayed implementation or suspension of planned activities

- Implementation of unplanned activities to contain the pandemic strained the expenditure of planned activities

Measures adopted included:

i. Technical

- Local production of some basic inputs and chemicals to substitute imports.

- Targeted messages and awareness creation on protocols involving handling and movement of fish and fishery products.

- Taking advantage of information and communication technologies (ICT) to improve inclusion, efficiency and environmental impacts. The use of mobile phones, through innovation platform (IP) for extension service delivery was very useful.

- Revision of 2020 sector work plan, particularly the timelines, budgetary allocations and deliverables

ii Economic

- Establishment of COVID-19 support schemes by Government to assist small and medium scale enterprises.

iii Social

- Education and sensitization on the need to observe safety protocols to minimize its spread.

___

Pests, Diseases, Symptoms and Control Measures

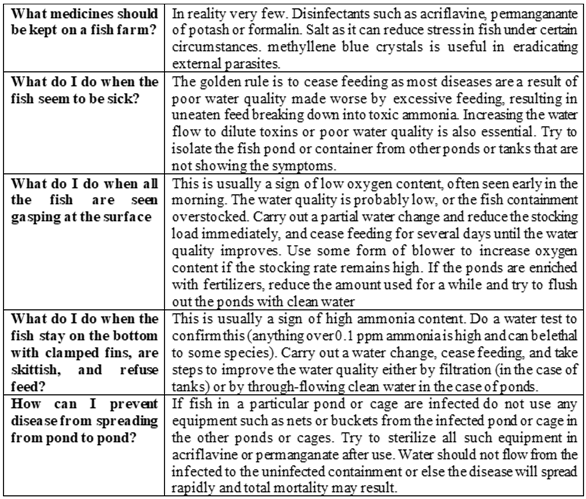

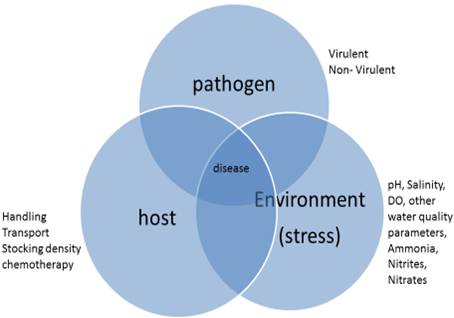

Disease occurs when the following three conditions exist: fish must be susceptible to the disease, the disease must be present, and environmental conditions must be conducive for the pathogen. Hence, using healthy fish stock, employing good management practices, and maintaining good water quality can minimise or exclude disease incidence.

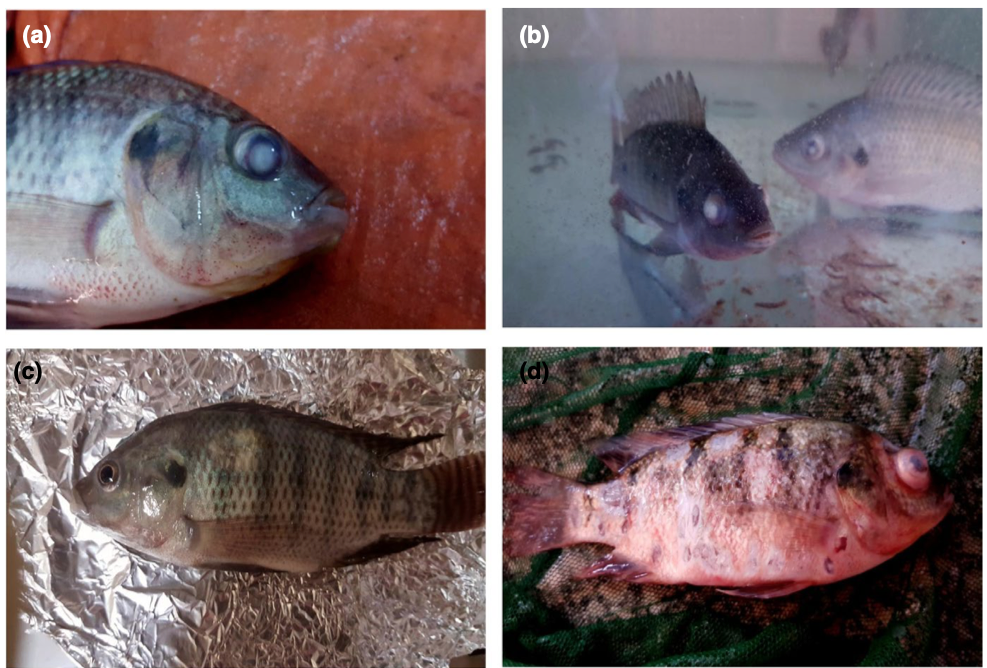

Some common signs of fish diseases

- Erratic swimming

- Gulping for air & crowding especially at inlets

- Rubbing of sides

- Off feed (refusal to eat or low propensity for food)

- Distended abdomen

- Pop/blind eye

- Wounds

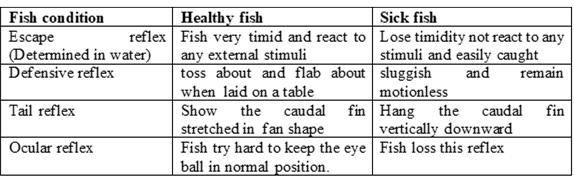

How do you know that your fish is sick?

The major disease problems affecting Nile tilapia and their control measures are listed in the table below.

| Diseases | Symptoms | Control and Preventive Measures |

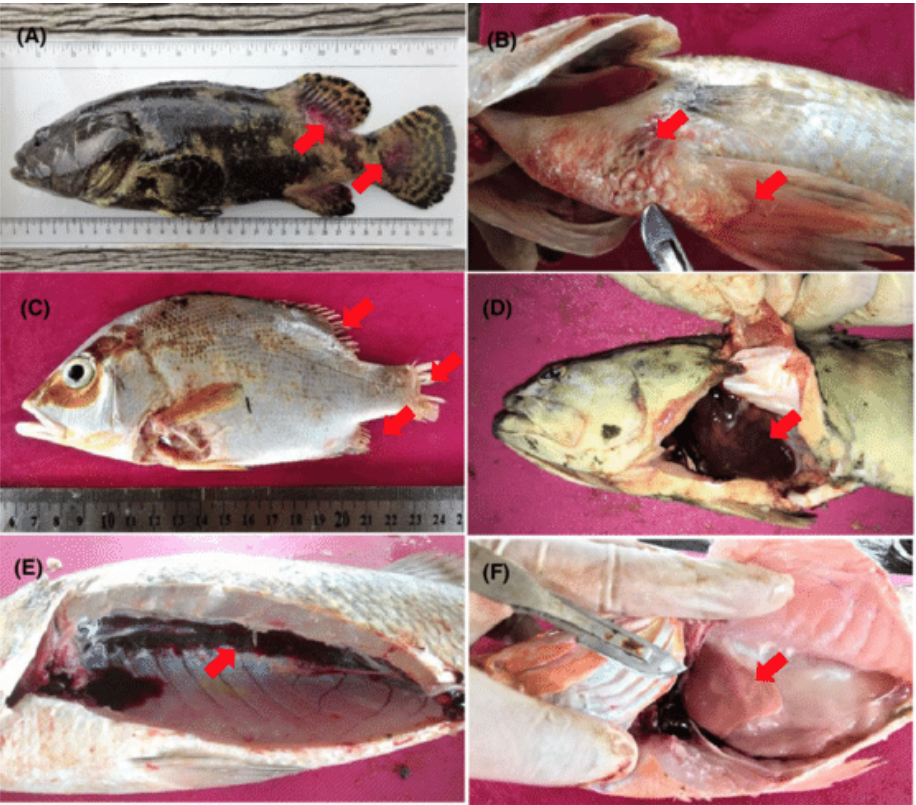

Motile Aeromonas Septicaemia (MAS)

| Loss of equilibrium; lethargic swimming; gasping at surface; haemorrhaged or inflamed fins & skin; bulging eyes; opaque corneas; swollen abdomen containing cloudy or bloody fluid; chronic with low daily mortality

| KMnO4 at 2-4 mg/litre indefinite immersion or 4-10 mg/litre for 1 hour; antibiotics; 21 d withdrawal |

| Vibriosis | Same as MAS; caused by stress & poor water quality.

| Antibiotic in feed |

| Columnaris | Frayed fins &/or irregular whitish to grey patches on skin &/or fins; pale, necrotic lesions on gills.

| KMnO4 as with MAS; indefinite immersion with CuSO4 at 0.5-3 mg/litre, depending on alkalinity |

| Edwardsiellosi | Few external symptoms; bloody fluid in body cavity; pale, mottled liver; swollen, dark red spleen; swollen, soft kidney.

| Antibiotic in feed |

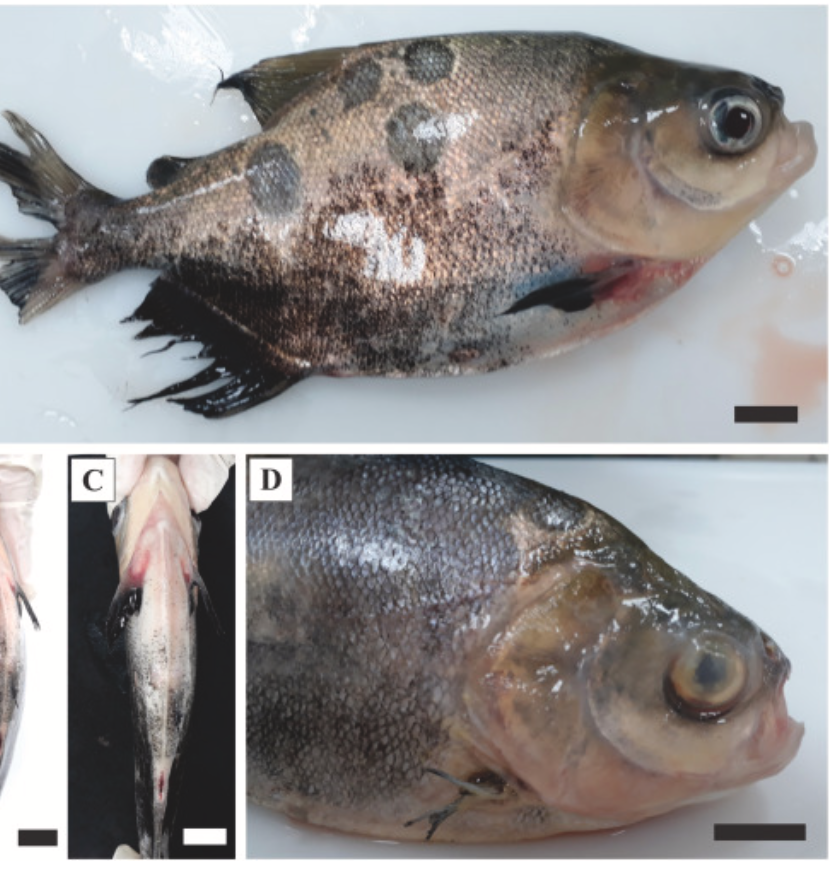

| Streptococcosis | Lethargic, erratic swimming; dark skin pigmentation; exophthalmia with opacity & haemorrhage in eye; abdominal distension; diffused haemorrhaging in operculum, around mouth, anus & base of fins; enlarged, nearly black spleen; high mortality.

| Antibiotic in feed, e.g. Erythromycin at 50 mg/kg fish/d for 12 days |

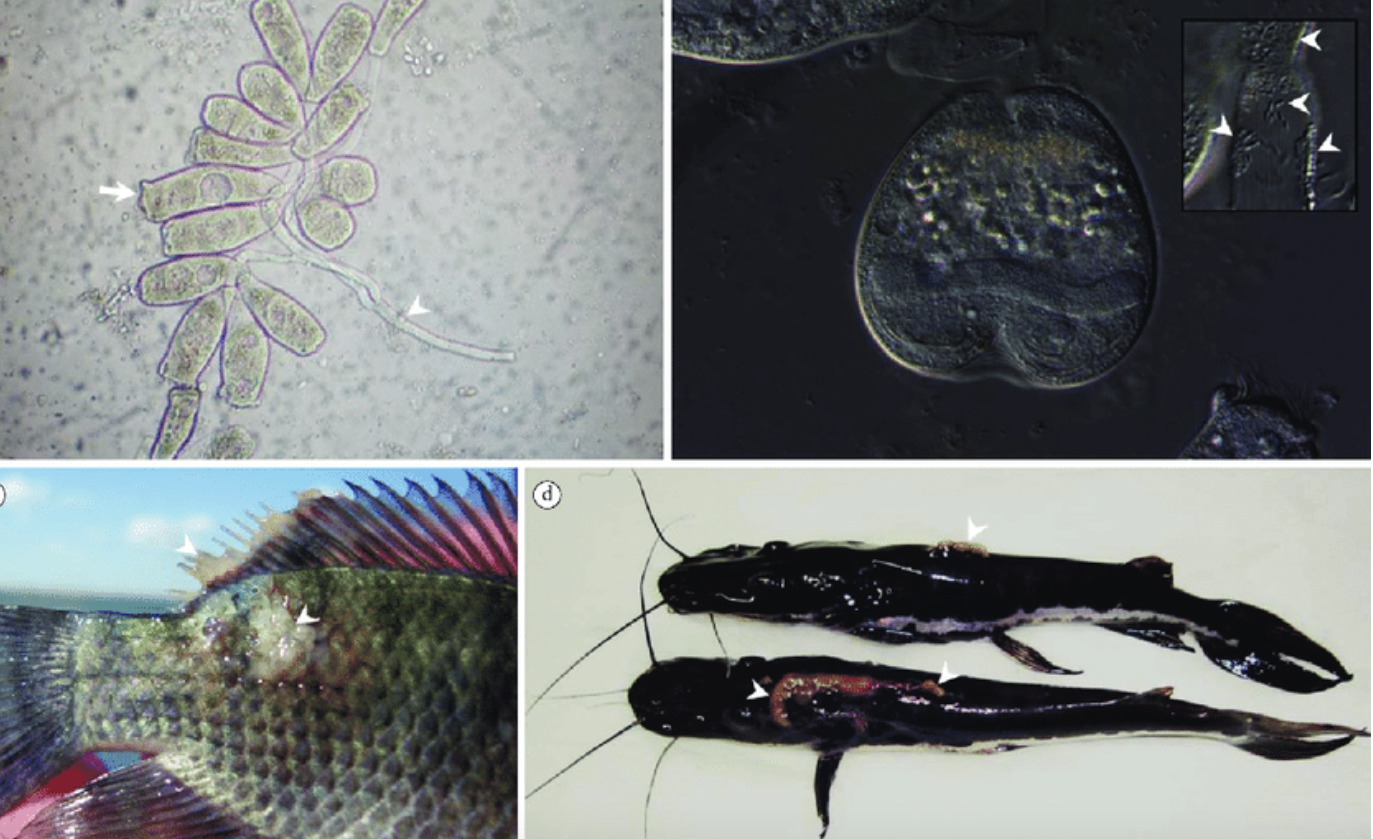

| Saprolegniosis | Lethargic swimming; white, grey or brown colonies that resemble tufts of cotton; open lesions in muscle.

| KMnO4 or CuSO4 treatments; use 1 mg/litre of CuSO4 for every 100 mg/litre alkalinity up to 3.0 mg/litre CuSO4; formalin at 25 mg/litre indefinite immersion or 150 mg/litre for 1 h |

| Ciliates | Occurs on gills or skin

| KMnO4, CuSO4 or formalin treatments |

| Monogenetic trematodes | Occurs on body surface, fins or gills

| KMnO4, CuSO4 or formalin treatments |

___

Market Information on Tilapia

Market Information

Tilapia is an important species of aquatic products traded in both domestic and international markets. Demand for fish and fisheries products has improved due to increase in global population. Again, the global captured fishery was declining following the incessant human exploitation for commercially valuable fish stock. Aquaculture or fish farming has, thus, been recognised as one of the solutions to maintaining the continuous supply of fish to commercial markets.

The aquaculture market is projected to grow from USD 30.1 billion in 2018 to USD 42.6 billion by 2023, recording a Compound Annual Growth Rate (CAGR) of 7.2% during the forecast period. This is attributed to the growing consumption of fish for its nutritional value

About 40 per cent of all fishes produced are traded internationally. Marketing strategy is one of the most important aspects of aquaculture business. It is important to identify a reliable market, and even a back-up market, before making capital investment

Recently, a fish marketing company, Aquatic Foods, started tilapia products development, processing tilapia into sausages and kebab.

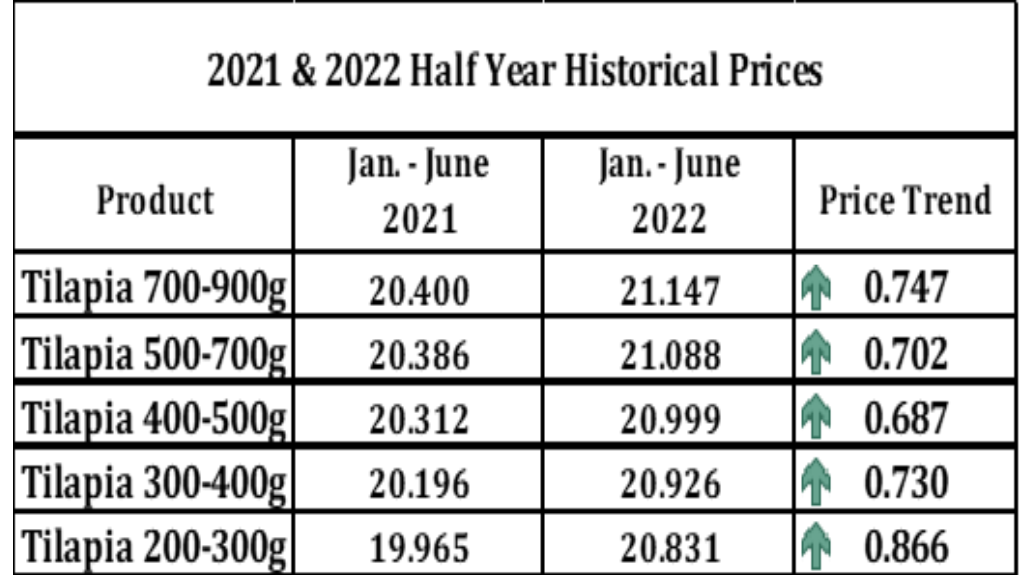

The cost of whole catfish and gutted tilapia fluctuated in the second and third quarters of 2020. From April 1, 2020, to September 30, 2020, the prices listed in the table 1 and figure 1 represent farm gate pricing for fresh, gutted tilapia and catfish.

Figure 1: Price Status of Tilapia and Catfish

The first half of 2022 saw a sharp increase in the cost of tilapia and catfish, particularly around Easter. The increase is linked to a rise in the price of fish feed components including maize, soy, and fish oil on the international market. The price increase of tilapia and catfish in Ghana during the first half of 2022 can also be attributed to an increase in import levies, a depreciation in the local currency against key foreign currencies, and a high cost of energy.

Figure 1: Half Year Prices Variation for Tilapia

Table 2: Half Year Prices of Tilapia in 2022

The third quarter of 2020 saw a healthy domestic market for farmed catfish and tilapia. Although the cost of tilapia and catfish decreased in the second quarter of the year, it has gradually risen in the third quarter.

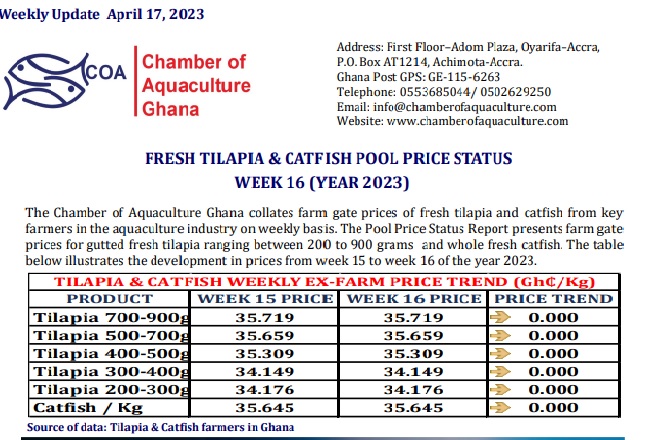

Weekly prices of Tilapia and Catfish https://www.chamberofaquaculture.com/chamber/2022pdf.html

___

Key Policies and Programmes

Permits for Aquaculture Operations

Aquaculture development in Ghana is governed by the Fisheries Act 625 of 2002 and Fisheries Regulations, 2010. A copy of the Act could be obtained at:-http://extwprlegs1.fao.org/docs/pdf/gha151991.pdf).

The following permits are required for establishing a fish farm: Environmental permit from the Environmental Protection Agency (EPA), water usage rights from the Water Resources Commission (WRC) and production permit from the Fisheries Commission (FC).

Key projects under implementation in the sub-sector include:

- Aquaculture for Food and Jobs

This is a flagship project of the Ministry of Fisheries and Aquaculture Development, aimed at enhancing domestic fish production and creating jobs for the unemployed and under employed youth along the aquaculture value chain.

2. Technologies for African Agricultural Transformation (TAAT)

The TAAT Aquaculture compact is one of the fifteen compacts comprising the Technologies for African Agricultural Transformation (TAAT) programme led by the World Fish Centre. The Compact aims at disseminating and upscaling Aquaculture technologies across Africa to increase farmers’ productivity, increase fish protein consumption and enhance sustainability across the Aquaculture value chain.

The technologies include Fast-growing quality fish seeds and improved fish rearing technologies: Tilapia (Oreochromis niloticus) and catfish (Clarias gariepinus, hybrids of Hetero-clarias), Quality low-cost fish feed using local raw materials and Improved post-harvest technologies and product development.

Specific objectives of the Aquaculture Compact include:

- To creating an enabling environment for aquaculture technology adoption by the value chain actors;

- Facilitate effective delivery of technologies to fish farmers and other actors along the aquaculture value chain;

- Increase aquaculture production and productivity through the identification and dissemination of quality tilapia and catfish seed, production of low-cost fish feed and value addition.

3. Tiseed Project

The Tilapia Seed project titled, “Accelerating aquaculture development in Ghana through sustainable Nile Tilapia seed production and dissemination” has an overall objective to improve productivity and profitability of tilapia cage and pond farming in Ghana.

It is a 3-year project (2019 to 2022), focused on tilapia seed improvement and is being implemented by a consortium of international and local research institutes, led by the International Food Policy Research Institute (IFPRI), supported by the CSIR-Water Research Institute (CSIR-WRI), KIT Royal Tropical Institute in the Netherlands, and WorldFish. Other partners are Fisheries Commission (a government institution) and two private hatcheries (S-HOINT Ltd. and Crystal Lake Ltd.). The project has multiple components including diagnostic study, capacity assessments of actors, household surveys, characterization of fingerling and tilapia genetic make-up and productivity performance via on-farm trials; interventions design via randomized control trials, and impact evaluation.

___

Weekly Update April 17, 2023

https://www.chamberofaquaculture.com/chamber/2022pdf.html

___

Email: Editor@agricinafrica.com

Comments

Post a Comment