Chilli Pepper Summary Fact Sheet

Production

- 145,121 Mt

SRID,2020

- 15,000 Ha

SRID,2020

- 134,146 Mt

SRID, 2020

- M I2

- Fresno

- Shito Adope

- Jalapeno

- Scotch bonnet

- Legon 18

- Bird’s eye

- Dried pepper

- Dry powdered pepper

- Chilli paste

- Domestic fresh

- Domestic dried

- Export market

- Intensive: Requires 2 to 4 times more labour than cereal crops

- 2 cropping cycle a year

- All year round under irrigation

Rainfed:

- March - April (Major season) August (Minor season) October (Irrigated sites): Southern Ghana:

- March - April (Rainy season) September - October (Irrigated sites): Northern Ghana

- All year round: Irrigation

- Cayenne (Legon 18): 60 × 60 cm

- Shito Adope: 60 x 30 cm

- Jalapeno: 60 × 30 cm

- Bird’s eye: 60 × 30 cm

- Fresno: 70 × 50 cm

- Scotch Bonnet: 80 × 50 cm

- 30,000 plant per Ha (depending on the variety)

- Chemical fertilizer which consists of Nitrogen, Phosphorus, Potassium, Phosphorus, Calcium etc.

- Organic manure (which includes poultry manure and cow manure)

Productivity

- 30 Mt/Ha depending on the variety

SRID,2020

- 8.8 Mt/Ha

SRID,2020

Budget Benchmarks

- GH¢ 28,171.70

- GH ¢ 56,250.00

- GH¢ 32,078.30 per Ha per

- Ghana has a comparative advantage over India which is a major competitor in the chilli export market

- Ghana chillies have a good reputation in the EU market attributable to Legon 18 variety which has a good taste and longer shelf-life

- 239,000 Mt with a growth rate of 8%

Risks

- COVID-19: Chilli production has been affected greatly due to unavailability of labour and hence all actors along the value chain.

- Foreign exchange variability or fluctuation.

- Increasing stringency by importing countries.

- High interception of exports

__

General Overview of Chilli Pepper Production

Chilli Pepper (Capsicum frutenscens) is the second most important vegetable crop in Ghana in value terms, serving not only as a key emerging non-traditional export commodity, but also as an important spice and condiment used in the diets of most Ghanaian households (IFPRI, 2020). Alongside tomato and onion, chilli ranks as one of Ghana’s three most important vegetable crops in terms of hectarage and crop value with significant potential for generating income, creating jobs, and contributing to foreign exchange through exports (Gonzalez et al. 2014).

Some farmers call it "green gold" because of its economic value to them. Production is done under both rain-fed conditions and irrigation during the dry season. Production of chilli pepper decreased slightly from 122,400 M/t in 2015 to 119,405 M/t in 2020. The area under chilli pepper cultivation in 2020 was 15,000 Ha with a yield of 8.30 Mt/Ha (FAOSTAT, 2020).

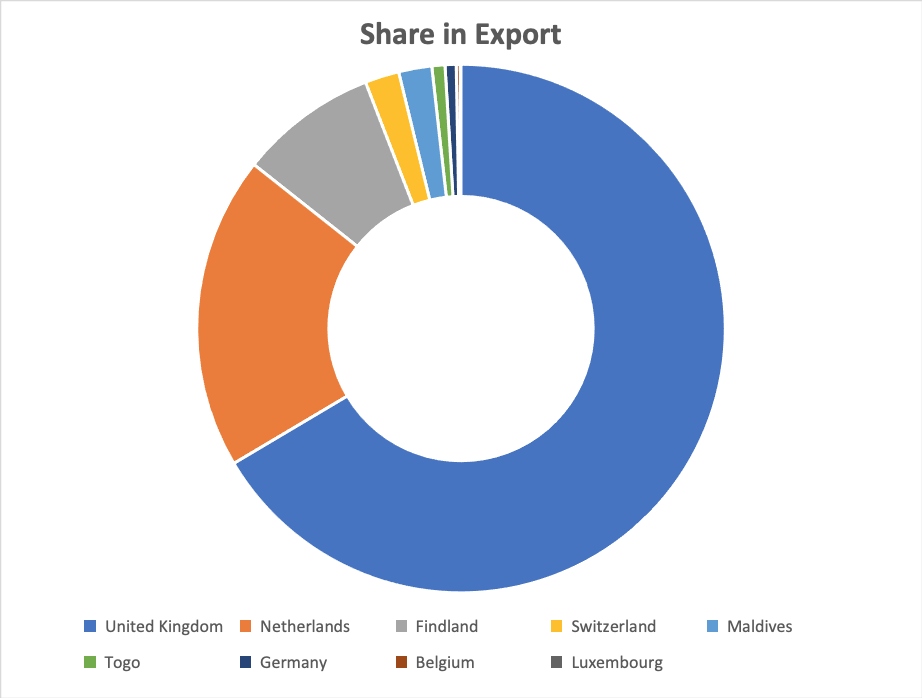

Chilli is a non-traditional export commodity for Ghana. The main export type is the green chilli. The main importing countries are United Kingdom, Netherlands, France and Germany (GEPA, 2017). The United Kingdom is the main destination for Ghanaian chilli. Ghana is also the largest chilli exporter to the United Kingdom outside of the European Union. This apparent comparative advantage is attributed to Ghana having a favourable seasonal marketing window to export to the United Kingdom as it coincides with the dry season in India, a major competitor in the chilli export market (Gonzalez et al. 2014). Chillies produced in Ghana are also known for their good reputation in the EU markets compared to chillies from other parts of the world, especially due to the Legon 18 variety (famous for its great taste and longer shelf-life). The Bird’s Eye chilli variety also offers an emerging opportunity for higher value chilli exports in Ghana (MiDA, 2010).

A thriving local and international market for chilli exists in Ghana with great potential for growth and investment. While chilli is mainly exported in its fresh form, in local markets it is sold in various forms, including fresh, dried, powdered, as a paste, or as an ingredient in a traditional condiment sauce called shito. Demand for processed chilli products is rising as urban consumers increasingly prefer the convenience of processed foods (DAI, 2014).

This phenomenon suggests the need for improvement in yield and quality of the produce if Ghana is to benefit from these market opportunities.

Varieties Chilli Pepper

Among the suitable types are (Hot)- Legon 18, Long Red Cayenne, Bird’s eye, M12, Scotch Bonnet, Kpakpo Shito, Jalapeno and Fresno. (Sweet)- King Arthur, Florida Giant, California Wonder, Red Knight, Early Carl Wonder, Chinese Wonder, Yolo Giant.

Climatic and Soil Requirement

Chilli peppers grow best in sunny, semi-tropical, or tropical climates with an annual rainfall of 600 mm to 1,250 mm. Temperatures between 18 ℃ and 32 ℃ are optimum for good growth. Low humidity will result in poor fruit set owing to flower buds falling. Chilli peppers thrive in a variety of soil types. However, they flourish best on sandy loams rich in organic materials. Choose soil that is well-drained, has a mild slope, and has a pH of 5.0-7.0. (slightly acidic to neutral).

__

Chilli Pepper Value Chain

Input Supply

This includes seeds, agrochemicals (fertilizers and pesticides) suppliers. Some farmers use their saved seeds from previous harvest whiles others use open-pollinated seeds with low yields. Improved certified hybrid seeds which improve yields and offer higher profits, as well as incomes, are available in reputable seed shops across the country. The varieties available include M I2, Fresno, Shito Adope, Jalapeno, Scotch bonnet, Legon 18 and Bird’s eye. The last four varieties are normally exported.

The seed companies and agro-input dealers include

- University of Ghana Legon (seeds-Legon 18),

- Chemico (agro chemicals),

- Wienco (seeds and agro inputs),

- Yara (seeds and agro chemicals),

- Dizengoff Ghana (seeds, agro inputs, irrigation system and heavy machinery),

- Rijk Zwaan Seeds (seeds),

- East West seeds (seeds) and

- Syngenta Ghana (seeds and agro inputs).

Some of these actors have outlets across the country where inputs can be obtained. Smaller distribution outlets for certified seeds and agro-input include Agrimat (seeds, agro-inputs, irrigation system and heavy machinery), Agriseed (seeds and agro-inputs), Aglow (seeds and agro-inputs), and Tikola seed limited (seeds).

Finance

Most banks and microfinance institutions have agribusiness desks to assess the loan applications of clients to know how viable a project is; however, they are often reluctant to give out credit facilities to farmers, especially vegetable farmers due to a perceived high-risk attached to farming.

Production

The actors in this area are mainly farmers. They carry out a lot of activities including site selection, land preparation, variety selection, nursey activities, planting, irrigation, pest, and disease management, weed management, soil fertility management and harvesting. Chilli production provides income-earning opportunities for women and youth as they are the main actors during harvesting. Chilli pepper production is done under rain-fed and irrigation conditions.

A major challenge to pepper production in Ghana is the limited availability of improved certified seeds and high cost of labour during harvesting. For instance, Chilli pepper production is labour intensive which requires two to four times more labour than cereal crops. Knowledge and skills of chilli production are still relatively rudimentary in Ghana hence farmers face a lot of setbacks which lead to low yields. Average yield of chilli pepper (2015-2020) is 8.8 Mt/ha which is not comparable to the attainable yield of 30 Mt/ha (SRID MoFA, 2020). Despite the low yields of chilli pepper, it contributes 60 - 70% of farmers income (DFID, 2014). When farmers use improved varieties such as Legon 18 and Bird’s eye, with Good Agronomic Practices, exceptionally high yields (gross margin of $882/0.4ha) is achieved. Local varieties of chilli (Hwenyame) under the same condition is also profitable, but to a lesser margin (gross margin of $316/0.4ha) (GIZ-2012).

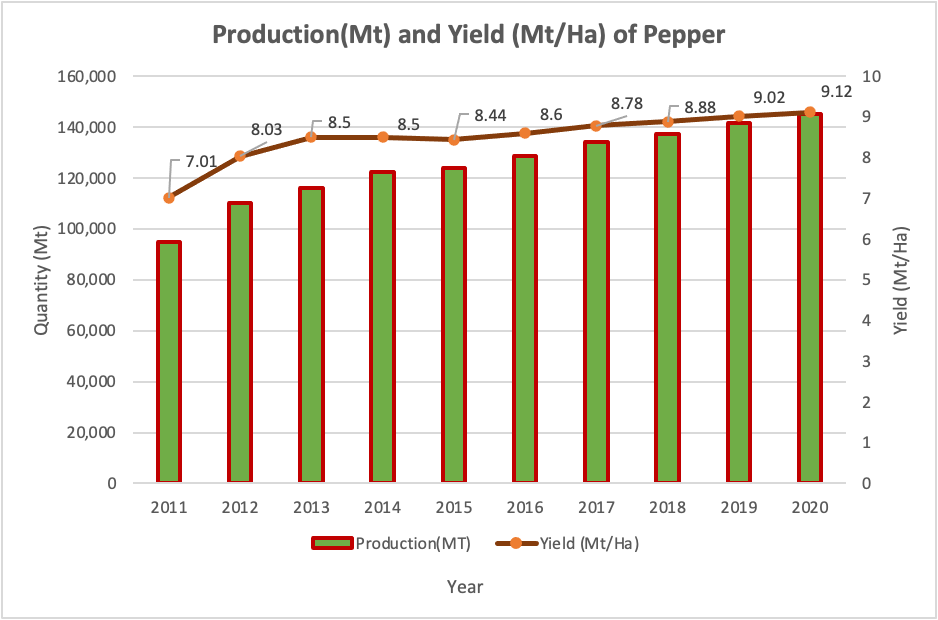

In general, production continues to indicate a relatively flat trend pattern. The pace of growth was most pronounced in 2012 with an increase of 110,000 MT. Chill pepper output peaked at 145,121 MT in 2020, but production stalled from 2016 to 2017. Production fell to 90,000 tons in 2011 due to a dramatic reduction in dry season irrigated chili production, which set a record for low yield. However, yields gradually increased in the years that followed (Gonzalez et al. 2014). According to official data, production increased between 2011 and 2019 from 7.0 to 9.0 tons per hectare.

Figure 1: Production of Chilli Pepper

Post-Harvest Handling

Demand for processed chilli products is rising as urban consumers increasingly prefer the convenience of processed foods (DAI, 2014). Post-harvest losses which occur during handling, sorting, grading, packaging, storage and transport pose massive problems to value chain. Chilli Peppers are perishable hence handling is very crucial to maintain quality and freshness.

To extend the self-life of chillies, value must be added after harvesting. Drying is an essential post-harvest activity because it increases the shelf life of the product. If farmers are able to dry and store their produce for a while, they earn higher incomes in the dry season since the seasonal nature of the pepper is associated with high price variability.

Processing

Demand for processed chilli products is rising as urban consumers increasingly prefer the convenience of processed foods (DAI, 2014). Chilli is processed into dried pepper, dry powdered pepper, and chilli paste. The powdered pepper is used in preparing a local chilli product known as Shito.

Chilli pepper is produced by a few companies in Ghana. These include EKA Processing Company (a major chilli producer in Sunyani) and two small chilli processing companies (Tamaiko Queen GAF), and JEGS Company Limited in Accra also process pepper into powder for the export market.

Marketing

Pepper is marketed in both fresh and processed state. Market power in the chilli value chain is tilted in favour of the buyers/traders who play a greater role in determining prices, especially during bumper harvests. There are three main market segments: the domestic fresh, domestic dried and export market. The fresh domestic market is buyer-driven as farmers receive a small proportion of final prices. The domestic dried pepper has value addition although significant losses occur during drying. After drying, processing into powder and other products adds extra value. The export market is buyer-driven with varieties and prices determined by exporters. Exported chillis are cultivated to meet GlobalGAP and other market standards, sorted and package for European supermarket notably Britain and Germany. Fresh chillies are sold mainly in the domestic market however some packaging is emerging to serve supermarkets and hospitality industry. The long and finger-like variety is most preferred for the dry chilli market whiles the round is also preferred for fresh chilli market. The market for both fresh and dried is growing rapidly with the sale of chilli powder growing faster. The fastest growth, though from a low base, is in the sale of finished products such as shito, as they cater for the trend towards convenience amongst urban consumers. Four major markets in the Southern belt of the country are Accra, Takoradi, Kumasi and Techiman. Agbogbloshie, Makola, Nima, Mallam Atta and Madina markets are markets within Accra where fresh, dried and powdered chill pepper can be purchased.

Consumption

Chilli pepper is consumed in both fresh or processed state. The national consumption of chilli has been 239 000 MT and this has been growing at around 8% per annum due to the establishment of hospitality industries, increased incomes and consumer preferences as integral to Ghanaian dishes (DFID, 2014). Fresh and processed chilli pepper are consumed by hotels, restaurants, schools and households.

__

Key Agronomic Practices

Key Agronomic Practices and their Importance

| Good Agricultural Practice | Brief Description and Importance |

|---|---|

Planting Material

| Used improved certified seeds from reputable dealers. Major varieties: Legon 18, Scotch bonnet, Jalapeno, Bird’s eye, M12, Kpakpo shito and Shito Adope. |

| Production Areas |

|

Nursery Establishment

|

|

| Land Preparation |

|

Planting

|

Spacing for some Pepper Varieties Cayenne (Legon 18)

Shito Adope Jalapeno

Bird’s eye

Fresno

Scotch Bonnet  |

Choose suitable soils

|

|

Agro Climate Conditions

|

|

| Staking |

|

| Mulching |

|

| Irrigation |

|

Pest and Disease Management

|

|

Soil Fertility Management

| Test soil to know fertility before applying fertilizer and adjust rates to meet the crop’s nutrients requirements. Nutrient Management

Weekly application of micro-nutrients (Iron, Zinc, Copper, Molybdenum, Boron, Manganese) should be applied to foster better plant development. |

| Weed Management |

|

Harvest Management

|

|

Post-Harvest practices

| Handling

Sorting and Grading

Packaging

Holding and storage

Transport

Drying Hot Pepper

|

__

Key Risks Along the Value Chain and Mitigation Measures

| Value Chain Actions | Key Risks and Challenges | Mitigation Measures |

|---|---|---|

Input Supply

|

|

|

| Finance | Difficulty in accessing loans and credit facilities.

|

|

| Production |

|

|

| Post-harvest handling |

|

|

| Marketing |

|

|

| Processing |

|

|

| Consumption |

|

|

__

Pests, Diseases, Symptoms and Control Measures

Major Pests and their Control Measures

| Pests | Symptoms | Control Measures/Management |

|---|---|---|

White Flies (Bemisa tabaci)  |

|

|

Aphid (Cotton aphid (Aphis gossypii)  |

|

|

Thrips  |

|

|

Mites (Tetranychus urticae)  |

|

|

Major Diseases and their Control Measures

| Diseases | Symptoms | Control Measures/ Management |

|---|---|---|

Damping-off  |

|

|

Phytophthora  |

|

|

Anthracnose Collectotrichum capsici, C. coccodes, C.acutatum  |

|

|

Fusarium wilt (Fusarium oxysporum f. pv. lycopersici)  |

|

|

Bacterial wilt (Pseudomonas solanacearum)  |

|

|

Cercospora leaf spot  |

|

|

Powdery mildew (Laveillu lataurica.)  |

|

|

Viral diseases  |

|

|

__

Market Information on Chilli Pepper

Chilli Pepper is produced in Ghana all-year round. The crop grows well in all the Regions of the country. Chilli Pepper is currently the leading vegetable export from Ghana with the main markets being the U.K., France, the Netherlands and Germany. With expertise in the production and marketing of the product, there are a good number of producer-exporters of the product who have access to a large pool of out-growers from whom they buy quality chilli pepper for export.

The market window for Ghana (March-September) coincides with the European growing season in southern Europe, which makes it less beneficial to the local producer and exporter. According to GhanaVeg, the import prices of Ghana chillies in the UK have become higher in recent years compared to India and Uganda.

To export chilli pepper to the European markets, one needs to meet buyer requirements. This is divided into:

- Musts (for example, legal requirements), which must be met in order to enter the market.

- Common requirements (which have been implemented by most competitors), with which you should comply in order to stay abreast of the market; and

- Niche market requirements, for specific segments.

There are also legal and non-legal necessities that a product must comply with in order to market your chilli pepper in Europe. These include minimum pesticide residues, quality, size, packaging, labelling and compliance with phyto-sanitary requirements.

Beside the above requirements, GlobalGAP. is an additional certification that is required for chilli exporters from Ghana. GlobalGAP. is a pre-farm-gate standard that covers the whole agricultural production process (excluding processing). GlobalGAP. requirement depends on the destination country, market channel and market conditions. Other food safety management systems that can be required are BRC (British Retail Consortium), IFS (International Food Standard), FSSC22000 (Food Safety System Certification) and SQF (Safety Quality Food Programme). The above systems are supplemental to GlobalGAP and are recognised by the Global Food Safety Initiative.

The chilli pepper domestic market is disorganised with the major market in the Southern sector and the Northern sector to a lesser extent. There are failures in market information and weak supply chain linkages in that, knowledge of market trends and what the market demands is mainly confined to large buyer/exporters. A few processors (Taimako Queen and GAF in the North and EKA Processing Company in Sunyani) exist however they do not, individually or in the aggregate, operate at a large enough scale to drive the market or supply chain.

Ghana exports a little amount of chili to neighboring nations. However, because the majority of regional commerce is informal, data is limited owing to underreporting and lax enforcement of trade restrictions at the border (van Asselt et al. 2018). According to some estimates, chili imports account for less than 2% of domestic consumption (Gonzalez et al. 2016; van Asselt et al. 2018), while a minor growth in imports in recent years has been ascribed to demand from supermarkets in metropolitan areas that serve middle-income consumers.

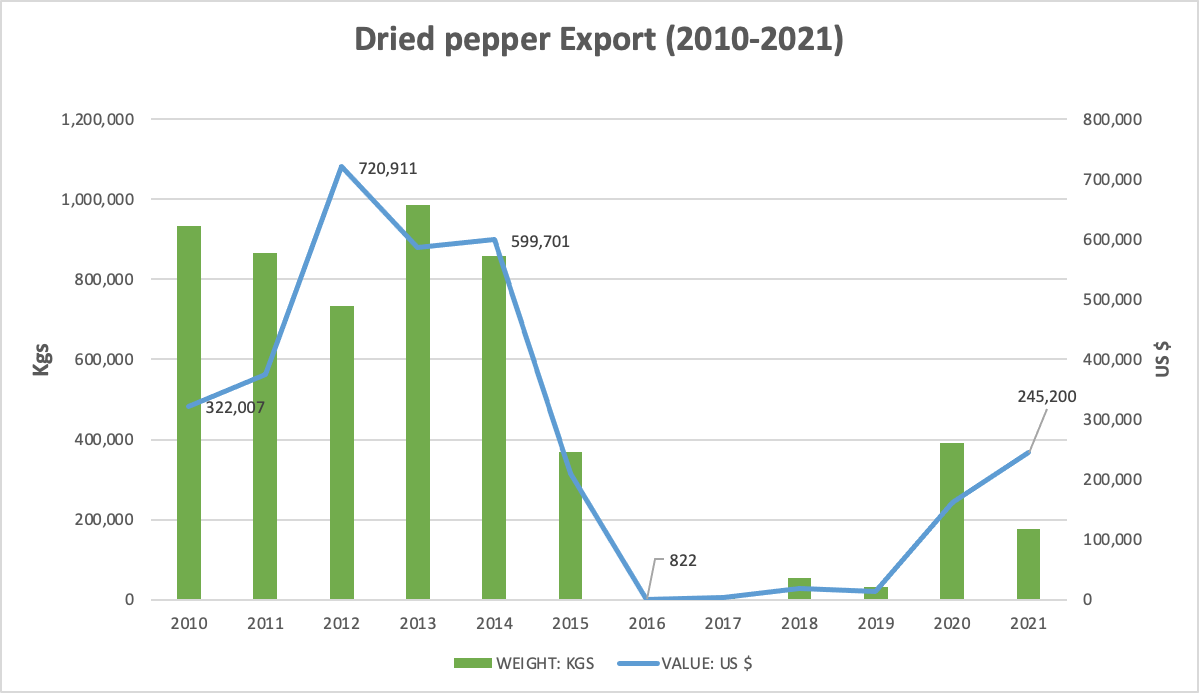

The graph below shows that there has been a reduction in the quantity of dried pepper exported from 2014 to 2019, . In value terms, export of dried pepper from Ghana sky-rocked to US $ 720,911 in 2012. Between 2015 and 2020, the trend pattern indicated a decrease in exports. This is due to the inability of Ghana to meet all the necessary EU phyto-sanitary requirements for export

Figure 1: Export of dried pepper

The United States of America (USA) is the world’s biggest market (60%) of chilli pepper. It is evident that there is a great market opportunity for chilli pepper exporters in the country if all the phyto-sanitary conditions are met.

Figure 2: Market destinations for Cilli pepper

Some companies who are into export of fresh chilli from Ghana are Maphlix Trust Ghana Limited, Param Farms, Delon Farms and Trosky farms.

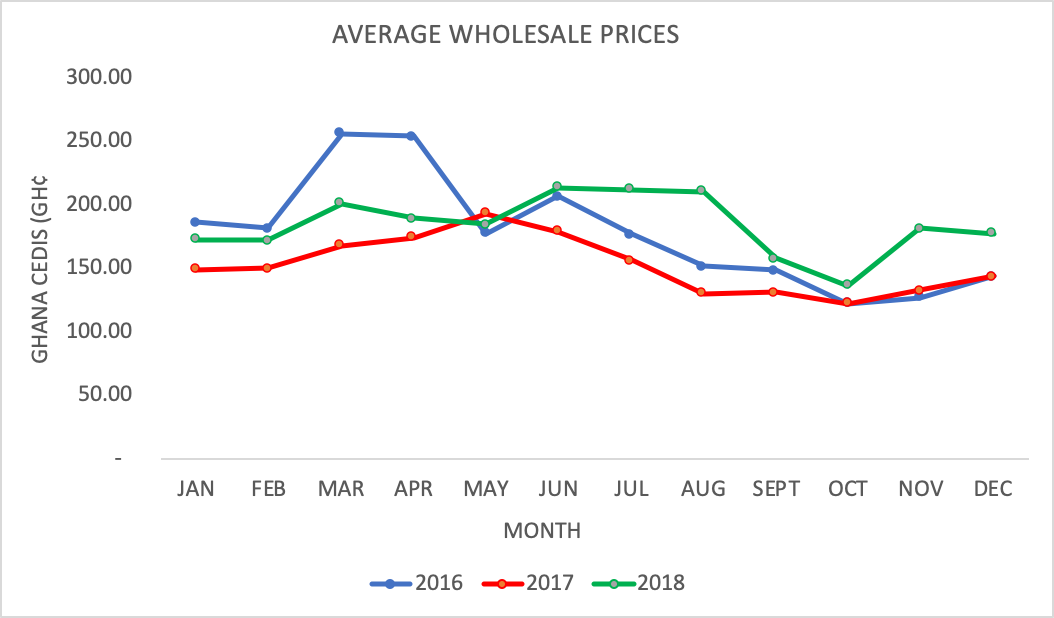

Price Trends

Prices of chilli pepper in the wholesale markets from 2016 to 2018 are highest in March and April whiles the lowest is observed in October. Processors can take advantage when prices are the lowest in order to gain more during the dry seasons.

Figure 3: Average Wholesale prices

Some Exporters of Chilli

| Company | Export Destination | Address |

BisaWorld Limited

| ECOWAS Market (Dried Powdered Pepper) | B461 Sanyo Road, Contact person: Milicent Koranteng Phone: +233 (0) 266033312; +233 (0) 266033309; +233 (0) 266033339 Website:http://www.bisaworld.com |

| Joekopan Enterprise | Germany United Kingdom | P.O. Box 1063 Osu-Accra. Contact person: Mrs Juliana Opuni Phone::+233(0)508126284 Website:http://joekopangh.com |

| Srighan Farms Limited | United Kingdom Sri Lanka | K. Kugathasan Contact person: K. Kugathasan Website:http://www.srighanfarms.com/ |

__

Enterprise Budget for Chilli Pepper

Estimated Budget 1 Ha per Cycle

| Activity | Total Cost (GH¢) |

| Nursery | 2,084.72 |

| Land Preparation | 6,165.00 |

| Transplanting & Fertilizer Application | 300.00 |

| Fertilizer Application | 4,038.00 |

| Pest and Disease Control | 4,207.95 |

| Irrigation | 2,475.00 |

| Harvesting | 3,750.00 |

| Total Production Cost | 23, 020.67 |

| Contingency 5% | 1,151.03 |

| Grand Total Production Cost/Ha/Cycle | 24, 171.70 |

Revenue Breakdown

| Revenue | |

| Average Fruits (Kg/Ha) | 25.00 tonnes =25,000.00 kg |

| Percentage loss (10%) /Kg | 2,500.00 kg |

| Average yield/(Kg/Ha) | 22,500.00 Kg |

| Packaging in box (6kg) | 3, 750.00 boxes |

| Farm gate price per 6kg box | GH¢ 15.00 |

| Total Revenue | GH¢ 56,250.00 |

| Total Production Cost | GH¢ 24,171.70 |

| Gross Income | GH¢ 32,078.30 |

Cost Summary

| Fixed Cost and Overheads | GH¢ |

| Amortization-Irrigation and other equipment | 2,500.00 |

| Staff Cost | 4,000.00 |

| Total Fixed Cost | 6,500.00 |

| Net Income | 25,578.30 |

__

Key Policies and Programmes

Key Policies, Projects and Programmes in the Sub-Sector

There is no specific policy for chilli pepper, however, chilli pepper is one of the priority vegetable crops under the Ministry of Food and Agriculture flagship programme ‘Planting for Food and Jobs’ (PFJ) campaign and the current national development strategy, Investing for Food and Jobs (IFJ) where pepper producers also benefit from the government fertilizer subsidy initiative.

Ghana Export Promotion Authority, Ghana Standards Authority and Food and Drugs Authority, provide export trade support by facilitating the promotion and development on non-traditional export goods (including chilli), the development and enforcement of standardisation and food quality control, including the enforcement of international quality standards.

The Northern Rural Growth Programme (NRGP) through Government of Ghana’s policy to commercialise vegetable cultivation in the Savannah belt identified chilli pepper as one of the vegetables which was supported under the programme. Improved chilli varieties, Integrated Soil Fertility Management (ISFM) strategies and greenhouse drying, and solar blanching techniques were introduced to the Northern Sector by SARI.

The Market-Oriented Agriculture Programme (MoAP) implemented by GIZ has been analysing and intervening in the chilli value chain. IFDC and GIZ have also promoted some interventions geared at integrating smallholder farmers into the domestic and international markets that enable farmers to increase the supply of raw materials and also participate in adding value activities to strengthen their position in the chain.

__

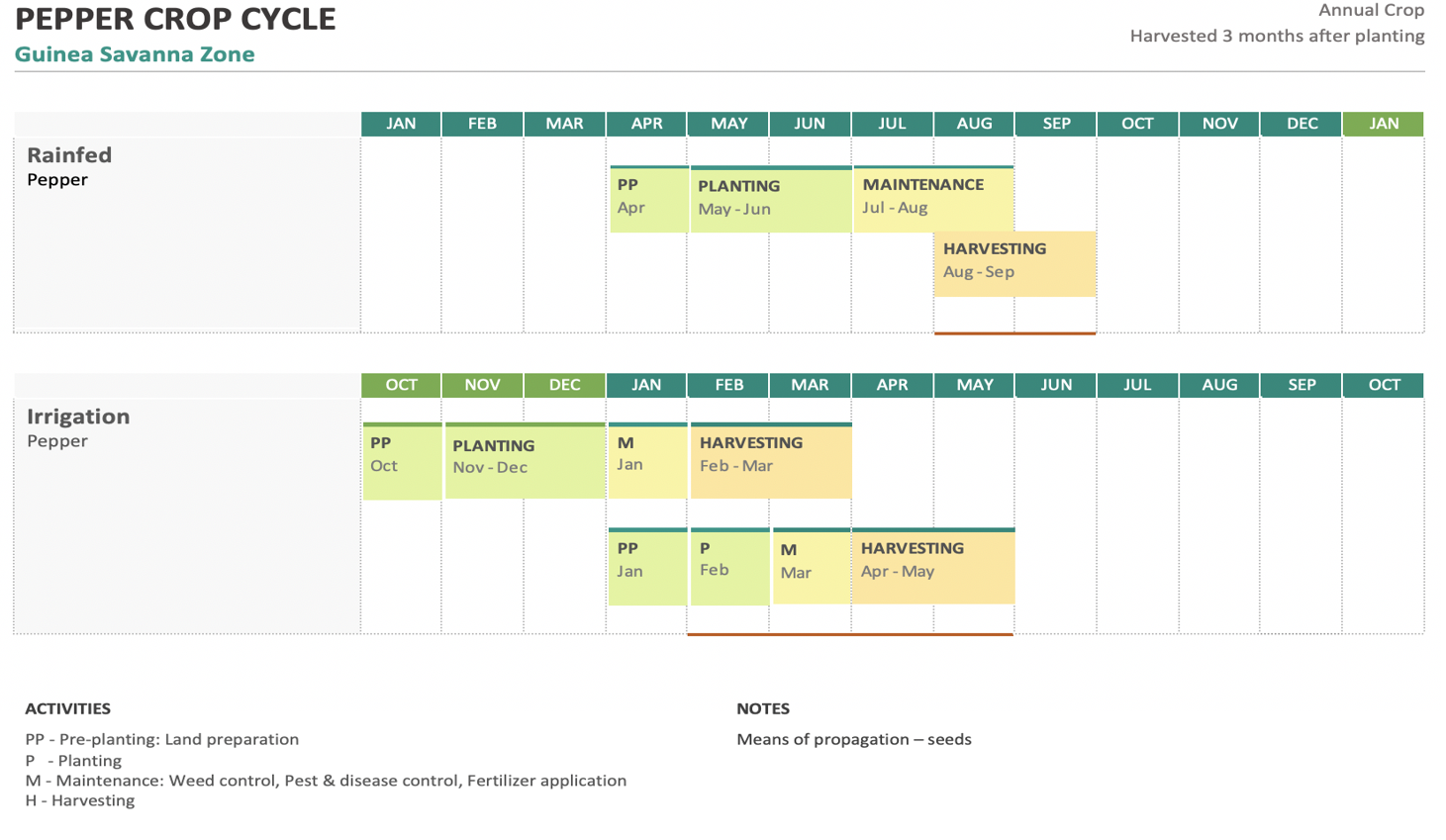

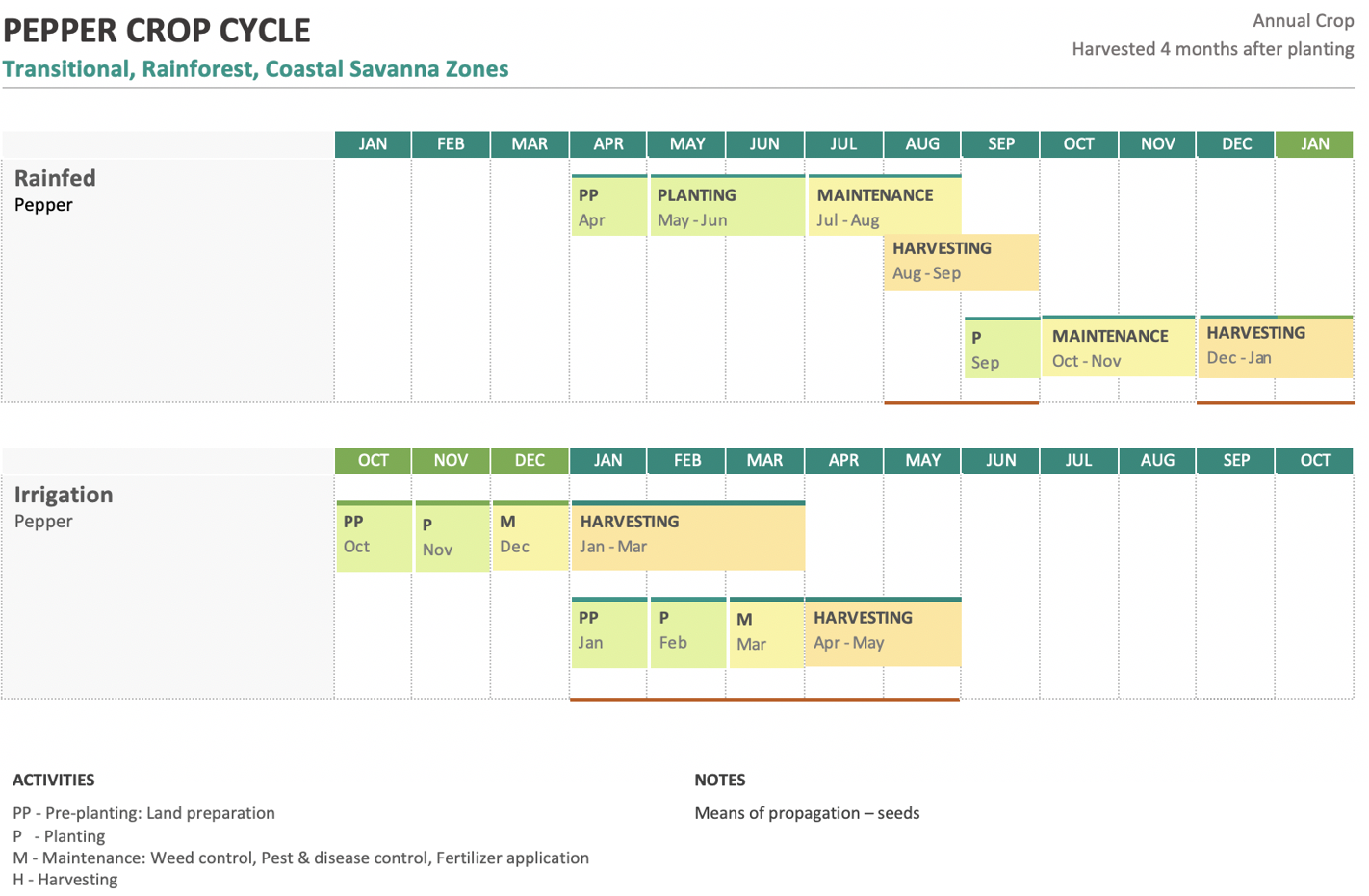

Chilli Pepper Growing Seasons and Cropping Cycle

__

Agriculture in Africa Media LBG| Email: Ghana@agricinafrica.com

Comments

Post a Comment